Neferteri Part Six

NEFERTERI part Six

What are you thinking?

Friends and family began to have serious concerns our Forrest Gump was a hoarder headed for the looney bin, as he kept dragging odd and assorted rusty parts and pieces home.

Larry Pointer found himself a survivor of Y2K, retired, a widower, and a more or less empty nester. He needed a project. In this series, he shares his passion for all things “Streamline Moderne”, and how it all turned into a 13-year labor of love, to create “Neferteri“, his custom Diamond T truck.

By Larry Pointer with Rik Hoving

Neferteri, Part Six

Caution: Graphic scenes may be disturbing to the purist. Life is like a box of chocolates. You never know what you’ll get. Adult discretion is advised.

“Here’s the Deal,” the quirky TV detective Monk would say. Before unravelling a knotty tangle of clues to drive a line to Truth in each mystery.

I had a dream, a drawing, and a forlorn tangle of tin and kindling, with no driveline at all.

Conquistador Dick Holcombe’s words kept ringing in my ears: “What are you THINKING?”

Here’s what I think. Car guys have this unhatched teenager inside them. Adolescents Anonymous. They go to garages, gather around shop projects, group in cruises, gaggle in lawn chairs at the Show and Shine. And yes, click into online forums for mutual support. Long live Custom Car Chronicle.

A few bricks short of a load, describes a lacking in the brain department. In addition to the obvious, I was a few building blocks short in my project, too.

Had I one, the Diamond T chassis had a flat frame, straight as a fireman’s ladder. But I didn’t. And that dog tag on the firewall said “49 mph”. I needed a more modern drivetrain. And a ton and a half hauler wasn’t what I had in mind. Maybe a long wheelbase pickup would fill the bill. I haunted vehicle graveyards, back alleys and farm fence rows, tape measure in hand. And after all that, the answer was sitting just across the street from me all the time: A 1983 GMC the neighbor kid was herding back and forth to school; a hand-me-down from his beet farmer uncle. I got it, then, pretty much for the price of the 700R4 he shifted it down the road with.

Diamond T flat frame chassis, straight as a fireman’s ladder.

Diamond T flat frame chassis, straight as a fireman’s ladder.

[divider]

Maximum speed of 49 MPH… of the original Diamond T would not do it for me.

Maximum speed of 49 MPH… of the original Diamond T would not do it for me.

[divider]

The 1983 GMC donar car… and stripped frame.

The 1983 GMC donar car… and stripped frame.

[divider]

My original sketch with longer cab and rear quarter windows.

My original sketch with longer cab and rear quarter windows.

[divider]

In my drawing, to keep proportions balanced, I had stretched the cab length and added a pair of quarter windows for interest. The design balanced out the long hood. Easily done on paper, not so much in metal. I needed more pieces. While I was looking, I might as well search for one of the later all metal structures from 1939 to 1949.

Forlorn cab in Buzz and Jerry’s boneyard.

Forlorn cab in Buzz and Jerry’s boneyard.

[divider]

All metal 1939 cab from Bob Ulrich.

All metal 1939 cab from Bob Ulrich.

[divider]

I scored an all metal cab from a local collector of all things Diamond T, Bob Ulrich. It was stashed on its back behind his house. Bob also had a full figured 1948 Diamond T truck, mounted on a Chevrolet chassis, and I learned a lot from just how he made it fit together.

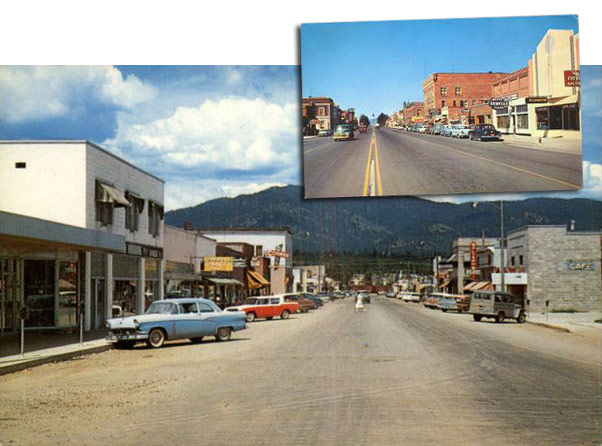

Then I had another lesson in just how small a World it is, after all. Ken Warren was a draftsman who had worked with me years before. He also was a car guy, and even before all that, he told me he used to hang out at Howard Edwards’ machine shop in Sheridan, Wyoming. That’s Conquistador mecca to me, and today is the shop of CCC contributor Scott Stalick! From Ken I learned of another early truck with the low windshields, a 1937 model, in his dad’s farm boneyard up on Montana’s High Line, only eight miles from Canada.

CCC member Scott Stalick in his shop,which is old Howard Edwards shop.

CCC member Scott Stalick in his shop,which is old Howard Edwards shop.

[divider]

Gregg Clark, Larry, and Mr. Warren with the 37 “lemon hauler” gruck cab.

Gregg Clark, Larry, and Mr. Warren with the 37 “lemon hauler” gruck cab.

[divider]

CCC readers, here’s another “Small World it is” point: Ken’s dad told me that he had gotten his Diamond T from an over the road trucker, and that it had been used, back in the day, to haul lemons from Los Angeles to New York. It even had gone through Death Valley in its journeys. When, now years later, I told Memo Ortega this story, he told me this:

“When I was a kid, I used to go down to the loading docks and load oranges and lemons into trucks. There was this old guy, he was really nice to me, and he had a Diamond T. It had a low windshield like yours, looked chopped. I always remembered how nice he was to me, and his Diamond T stuck in my memory because of that. He hauled lemons and oranges back East.”

From left to right: Larry Pointer, Terry Ortega, Memo Ortega.

From left to right: Larry Pointer, Terry Ortega, Memo Ortega.

[divider]

Is it possible that the truck Ken Warren found for me way up on the Canadian line could have been the very truck Memo Ortega had loaded with oranges and lemons in LA, to go “back East”, maybe to New York, as Guy Warren had told me. Coincidence? I have to tell you, both Memo and I had tears come to our eyes.

Citrus packing house.

Citrus packing house.

[divider]

One more: Britton Wicks, down my street, also is a car guy. He took notice of my hunter/gatherer behavior. “I have a photo of an old Diamond T like yours. My uncle drove one through Yellowstone Park, hauling new cars to Montana.” Then he shared his photo. Here were two Diamond T flatbed trucks, loaded with brand new 1936 cars, standing at the top of Beartooth Pass outside Yellowstone Park. Could one of those actually be the very Diamond T I first found, at Buzz and Jerry’s Rod Shop?

Two 1936 Diamond T model 212 trucks hauling new cars.

Two 1936 Diamond T model 212 trucks hauling new cars.

[divider]

Jerry LaFountain had purchased this truck from Lee Otis, a biker who built trikes for bad boys. Lee passed away right after, and many of the trim items for the truck never were located. Lee’s widow Deb is a waitress at the Hog Wild eatery, and she told me of the trip she and Lee had made to Deer Lodge, Montana to pick up that truck. The details there and back were pretty much faded images. On the hood panels, though, I almost could make out some painted sign letters. Turns out Deer Lodge Lumber had just such a truck in years past, and I could almost decipher lettering that could have confirmed it.

Diamond T logging truck.

Diamond T logging truck.

[divider]

The metal cab from Bob Ulrich came from up the valley at Columbus. A service sticker, though, was a clue that in an earlier life it had been a logging or mining truck up north out of Libbey, Montana.

Cab pieces and fenders in my shop.

Cab pieces and fenders in my shop.

[divider]

My pile of parts was growing. Now I had three cabs, two sets of running boards, some extra fender tatters for patch panels, and even sundry pieces from yet another cab Buzz Franke’s carpenter friend Ron Daigle found up a draw from a ranch house he was remodeling, down on the edge of the Northern Cheyenne Indian Reservation.

Then I discovered Leroy Gurganus. Leroy was the guardian angel of Diamond T’s. A retired trucker living in Jasper, Alabama, he had taken on a project of securing Diamond T production records, chassis number sequences, by year and by model and, through contacts with owners, a running record of survivors among those “Cadillacs of Trucks”.

I gave Leroy the information I found on the record plates located on each of the cabs I had collected. Soon, he wrote back with detailed information as to just what I had.

The Buzz and Jerry Rod Shop Diamond T, chassis # 205178, cab # 1663, was a model 212AD, a 1 ½ Ton Deluxe model (the D stood for deluxe). It was number 802 of 4899 built, and most probably was off the line in November, 1935. New, it cost $595.

Leroy Gurganus letter with all the info on the parts I had.

Leroy Gurganus letter with all the info on the parts I had.

[divider]

The all metal cab I had gotten from Bob Ulrich was a 1939 Model 406, number 739 of 911 built, and also a 1 ½ Ton model. It cost $950 new.

That lemon hauler possibly from Memo Ortega’s LA…picked up from the Warren family in northern Montana…was a 1937 Model 360, a bigger 2 ½ Ton truck, but also a Deluxe. It was produced late in the year, and sold for $1675. It had the low windshields of the 1937 model year and the highly desirable Deluxe dash.

From the beginning I documented the whole process, and every little details of the plans I had for the Diamond T.

From the beginning I documented the whole process, and every little details of the plans I had for the Diamond T.

[divider]

“I may not be a smart man, Jenny, but I know what love is.” These simple words from Forrest Gump pretty much sum it all up. Leroy Gurganus was a selfless, sharing man. Qualities we most admire. He helped countless ones along the way. Without a second thought, asking nothing in return.

Leroy Gurganus, Buzz Franke, Memo Ortega. Friends found unexpectedly along the way. Brilliance dwells in every one of us. We only have to remain open to be blessed with the light from others. I remember Forrest Gump scrubbing floors with Bubba Blue, and staring transfixed as Bubba rattled off his many ways of preparing shrimp. There have been many who have shed light on my awkward Adolescents Anonymous path.

As the Olympics played out on the World stage, the most memorable snapshots we tuck away are not the litany of medals and ribbons, but the human stories behind the hype and glory. The struggles to arrive and achieve, the sacrifices, and those unsung heroes who stopped and helped others who had fallen. The story of Neferteri is not an “I did it all myself “ tale. In large part it is a tribute to friends; my small way of passing it on.

Scott Clark is another to offer the helping hand. Scott came from a jack-of-all-trades ranching background. He has the ability to visualize everything in 3D. With the opportunity, he would have been a mechanical engineer, but the school of Life gave him skills that no formal education could offer. Scott’s Mobile Welding, he called his small business. I was ill prepared for this excellent adventure that would consume me for the next awkward thirteen years of my perpetual adolescence. My dented Monkey Ward toolbox dated to the Sixties; the tools sundry and assorted survivors. My own skill set, suspended in the lacquer mists of Time. I rode shotgun in Scott’s welding truck to jobs large and small, and watched him straighten, form, and attach metal in myriad ingenious ways. Along the way, we would stop by pawn shops to add to my tool set.

I soon had what had once been the neighbor boy’s daily driver stripped down to a bare chassis in my driveway. Shuffling my disassembled cab pieces, with poster board I laid out a template for the base of an extended cab. Scott helped me visualize a platform of square tubing for the Diamond T cab to bridge the dip in the GMC frame. Solid stanchions were fabricated in 1/8 “ steel to support the cowl, and the whole works located for critical clearances. I then cut a floor plate out of 10 gauge steel, with the trusty solid-foot Sawsall that Buzz Franke had taught me to use.

The platform of square tubing I fabricated for the Diamond T cab to bridge the dip in the GMC frame.

The platform of square tubing I fabricated for the Diamond T cab to bridge the dip in the GMC frame.

[divider]

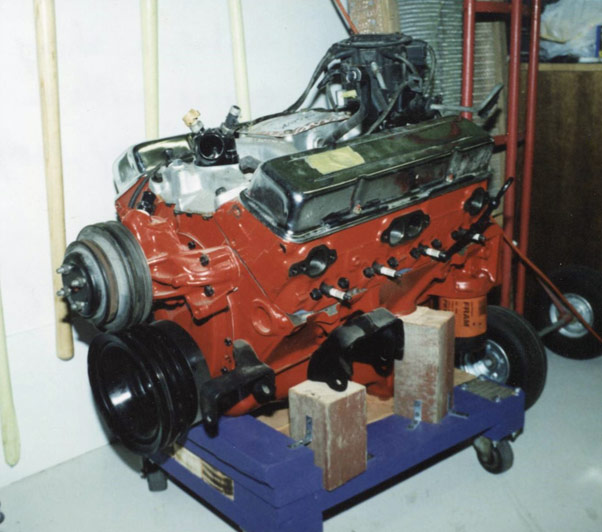

The GMC small block served mock-up early on, but was a pretty tired mill. Over in the corner of Buzz Franke’s shop, I spied a 350 engine on a dolly. “That belongs to my son,” Buzz told me. “But I think he’d sell it.” Turns out the high compression engine had been built by a legendary local street racer nicknamed “Rev”, and purchased with the idea of putting it in a Camaro for Eddie Franke’s step-daughter. The teenager had just gotten her driver’s license. Then her mom learned of Eddie’s plans with the hopped up motor. It was one of those “What are you thinking?” moments. She shut him down.

Yes, the small block was on the sale block. I bought it.

Jack Whittington working on the engine.

Jack Whittington working on the engine.

[divider]

“It takes a village to raise a child” it’s been said. Too true, especially for one such as me, stuck in perpetual puberty. Back in the Seventies, our babysitter was the boy across the street. By the 21st Century, Jack Whittington was an Air Force veteran mechanic with a pair of boys of his own. When we re-connected he was twisting wrenches alongside his brother-in-law John Stroble, an ace transmission rebuilder. They both became infected with the Neferteri virus, and took on her mechanical systems. Once I cleaned up the GMC chassis, assembly began in earnest. John rebuilt the 700R4 and my Chevrolet orange engine was nestled into its new home.

It seems like every moving part on that GMC was worn out. Scott Clark heated up the U-joints and their seals melted out like 4th of July firework snakes. Then he put in new U-joints and carrier bearing. John and I took on the brakes. Jack changed out the rear end pumpkin with a 3.73 gear set and began running wires through metal tubing for an Air Force sanitary set-up. I built lowering blocks to drop the rear, and Jack installed dropped spindles up front for that just-so stance.

Top photo: John standing on the left and Jack under chassis. Bottom photo: Jack, brother in law John Stroble, and me.

Top photo: John standing on the left and Jack under chassis. Bottom photo: Jack, brother in law John Stroble, and me.

[divider]

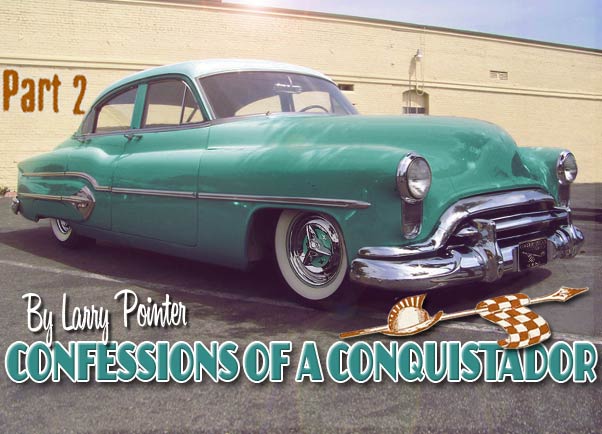

Almost a roller. Wheels! How could I make this “streamline moderne concept” truck look like it rolled out in 1936? The original Diamond T’s had some handsome cast Budd six-spoke wheels. Those big truck wheels were 20”, though, and wouldn’t adapt to the 83 GMC.

What to do? I shied away from the billet aluminum Aftermarket offerings. They didn’t’ fit at all with the Art Deco look. I really liked the spoked and scalloped artillery wheels that were all the rage into the mid-Thirties, then seen no more. I scored a set of 1936 Buick artillery wheels at Buzz and Jerry’s Rod Shop. Perfect, almost. They were 16”, with the right bolt pattern, but too narrow to take tires designed for today’s highway traffic.

Then I had an idea. I drilled out the rivets that attached the centers, then got some 16” rims from Dietz Salvage, and removed their centers. Johnny Sprockett at Sprocket Welding (honest, that’s his name) then welded the 1936 centers into the wider Chevy truck hoops. He changed the offset on the rear wheels, to correct the different front and rear track widths of the stock 83 GMC chassis. I never did understand why track widths on utility vehicles had that quirk. And now, the rear wheels even had that deep, reversed, look. Almost like I was running duallies.

A set of baldie hubcaps and there we were. I had a complete rolling chassis, a cowl and floorboard. What I needed next was something to sit on. Back to the salvage yards to search for the perfect car seats.

What are you thinking, you ask? Of all the advice along the line, perhaps the best in building a vehicle from scratch is to start with the comfort zone. If you are cramped in the cabin, if the steering, pedals and controls are not within easy, relaxed reach, you never will be happy. If you are humped over the steering wheel like a monkey hugging a football, you twist in contortions to squint for traffic lights, your head scrapes the ceiling, and you bang elbows with your shotgun rider, no good!

Buzz Franke showed me a seat frame he had built. It was a simple angle iron rectangle. You could bolt seating onto it, and move it over the floorboard until you had the most comfortable location. I had marked out my floor with lines that showed the square tubing grid the floor was resting on. I could then locate some brackets to secure the seat frame solidly to the chassis frame below.

Plain floor board and the simple angle iron rectangle seat frame.

Plain floor board and the simple angle iron rectangle seat frame.

[divider]

Meanwhile, from the final position of the Diamond T cowl on the 83 GMC chassis, I was able to mock up front fender placement and, from the hood length, just where the grill shell had to be mounted. The original Diamond T fender brackets then were bolted to the frame, and a crossmember was built to mount the radiator cowling.

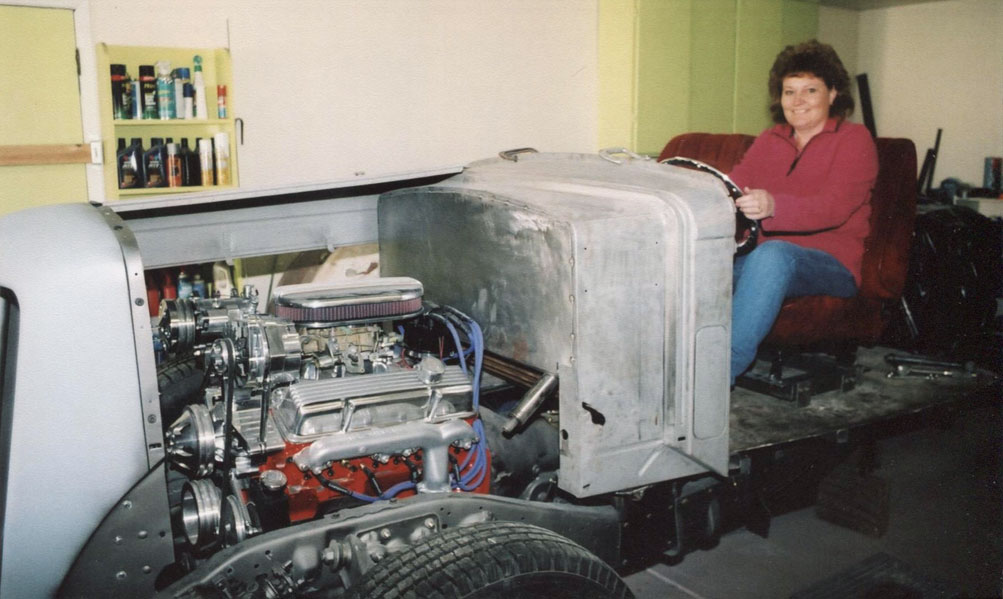

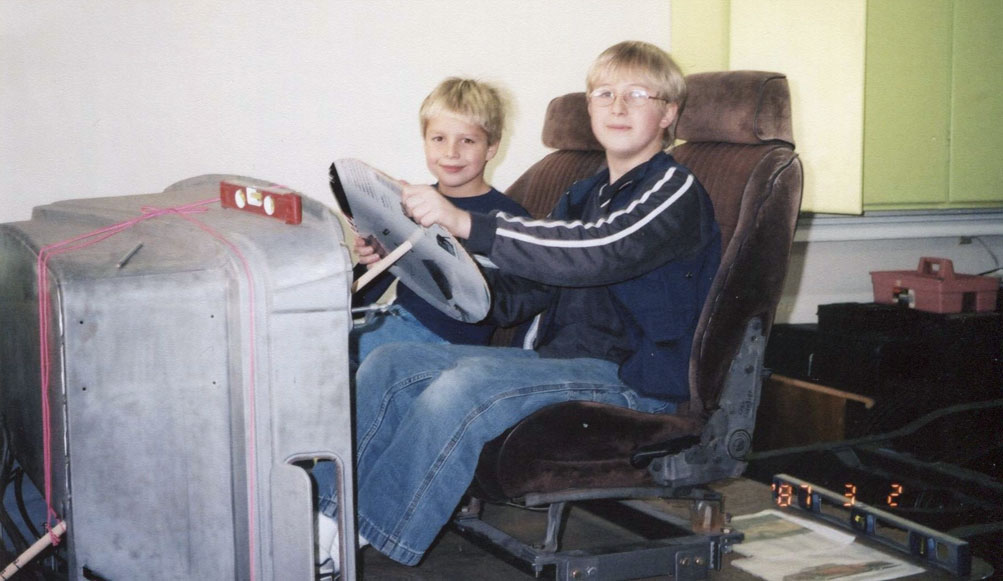

Next, I cut a length of wood dowel and tacked a pie plate on the end for a steering wheel. Then it was time to find that comfort zone. The mid-80s GM bucket seats I had scored (three sets before I was done!) were bolted to the angle iron frame. I C-clamped the set-up to the floor, and invited any and all to have a sit-down: Jack Whittington’s boys, my daughter Nicole, me, and Dotti Green. After 11 years of single cussedness, I found my soul mate in Dotti. We were married in 2005. I got her, two cats, and her saintly mother; she got me and a Diamond T. Pretty fair trade agreement.

My wife Dotti testing the first set of seats I found.

My wife Dotti testing the first set of seats I found.

[divider]

Daughter Nicole test fitting another set of seat.

Daughter Nicole test fitting another set of seat.

[divider]

Cole and Eric Whittington set fitting the state of the art steering wheel.

Cole and Eric Whittington set fitting the state of the art steering wheel.

[divider]

Larry Pointer, our Forrest Gump… ” i’m driving…”

Larry Pointer, our Forrest Gump… ” i’m driving…”

[divider]

Next, back to the future in the Egyptian Revival of Queen Neferteri.

(This article is made possible by)

![]()

awesome,,awesome,,awesome, story an a lot of awesome photos an details on the truck an what u did larry on it props to u an rik for bringing this story on ur nerferteri for all of us to enjoy in the ccc,

Really neat story! I bet it was the same cross-country orange and lemon truck…what a small world. 🙂

🙂

Torchie

Not bad…

HAHAHAHA!

Love it!!!

The artillery wheels were a great choice for your Diamond T.

When you’re given lemons.. Or something to that effect. This continues to be an extremely entertaining story. Thanks!

Dave