Citric Acid tutorial Part 2 HOW TO CLEAN METAL

- This topic has 4 replies, 5 voices, and was last updated 6 years, 8 months ago by

Larry Pointer.

Larry Pointer.

-

AuthorPosts

-

July 27, 2017 at 07:16 #52374

kustomlandParticipant

kustomlandParticipantPART TWO HOW TO CLEAN MEATL ” CITRIC ACID ” Method

After many years of cleaning metal in many forms the 2 worst ways I found was ” SAND BALSTING ” BEED BLASTING ”

Both ways are done with different types of material from SOADA BALSTING / GARNET/ GLASS / ALL GRITS OF SAND UP TO 40 GRIT / ILMANITE WITCH RUSTS ON CONTACT WITH WATER.

The only form that works in this process is Blasting with ” WALL NUT SHELL ” It is soft and does not heat the panel.

In 2010 a sandblasting company was contracted by a guy who had no clue into what he was doing took a GENUINE SHELBY FORD COBRA to a blaster in California. ” I wont name the company for legal reasons. ” This was a huge mistake waiting to happen as the blaster had no idea of HISTORIC CAR VALUE and the owner wanted to cut a cost. So The SHELBY COBRA HOOD was taken in on its own and given to them…….. Not long after the company began to blast the ALLOY hood as they never established the material before starting the $15,000 HOOD began to completely fold in on its self from the huge amount of heat until it curled and was un repairable.

So if any type of blasting is to be done I recommend ” WALL NUT SHELL ” Tho not many do it but people are around who do.

The issue is most people who Sand blast something are just JOE SHHMOE’S and will destroy just about every thing you give them not to mention they will not bother to tell you what they are using, But will tell the average guy just drop it over there and ill blast it……!

I have also seen the damage this also does to ALLOY MANIFOLDS. How ever there is a way to repair a ALLOY manifold that has been bead blasted….

In Salinas C.A there is one of the best engine builders in the world ” SLADE ENGINES ” Bob Slade has been building Formula 1 engines for 50 years and there expertise is so high They build FERRARI / Mc Claren / COSWORTH and lots of exotic engines to a level not many ever see unless you are in the factory were there made in. I was shown the process of restoring Alloy manifold’s that were Bead blasted and damaged.

The manifold is put into a special agitator with triangle ceramic beads and the manifold is agitated for several days until the alloy has its original surface finish. In 2011 / 2012 One of the most historical F1 cars the ” SHADOW ” from 1976.it was the back up car as the American driver was killed before the race doing a lap to gain his starting position in the race. It was HISTORICALY RE FURBISHED in every correct way not to loose its originality to be sold at PEBBEL BEACH MONTERY AUCTION. The car was sold for $16,000000 sixteen million.

I have always found fixing parts with rust a head ake constantly trying to find the correct way to bring tin to its original state with out causing issues for my self. As a painter I can not cut a corner on this stage because I know the amount of prep I will need to do to paint the same item I have striped. So I am not able to pass the buck onto the next poor guy and make it his issue……

So let me begin to tell you that the most perfect way to this process is so simple it can be done at home.

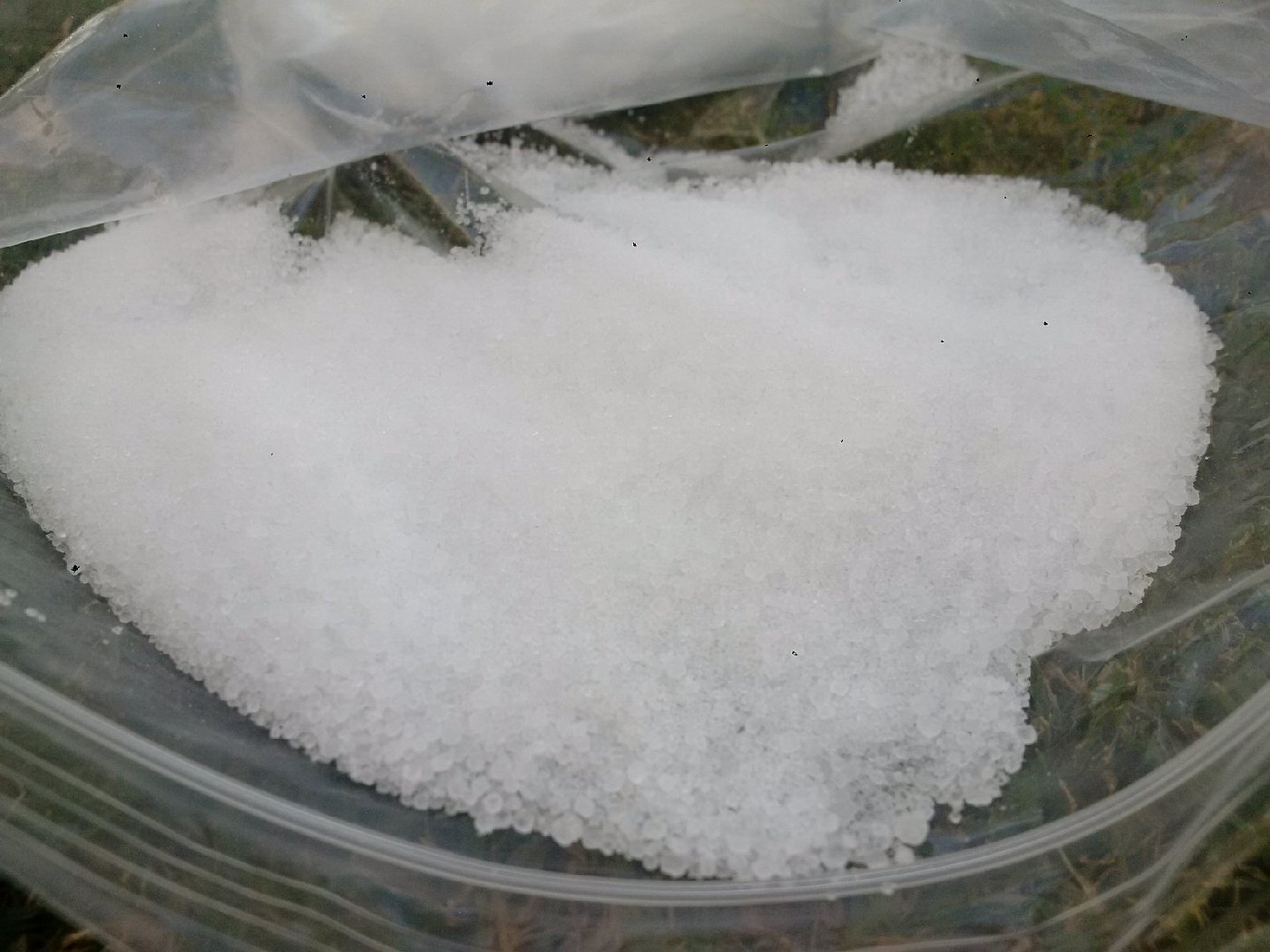

Citric Acid Formula: C6H8O7.

This is also the same stuff they use on sour candy. It comes in the from of crystals.

I had a huge issue with a motorcycle tank that was rusted on the inside and the only way I thought it could be fixed was to cut it open and bead blast it but I new it would change the composition of the metal in the inside forever.

Citric Acid only eats rust and is even harmless to original paint and will not damage it in any way. It will not clean grease. It will only eat rust and polish BRASS / COPPER / ALLOY / BRONZE.

So after cutting a motorcycle tank open I was informed by an old man who restores INDIAN MOTOCYCLES TANKS that I was doing it all wrong……As a person willing to learn new and better ways I asked him to show me his process and boy was I amazed. I had even tried using pool muriatic acid and it was so dangerous I left the parts for too long and they were completely eaten away…….!!!!

So I wish to explain and show the easy process that Citric Acid offers that will no dought change the way many people will now try to restore even there screws nuts and bolts….!!

WHAT YOU WILL NEED…………

Go to your HOME DEOPT and you can by a plastic trash bin for $20

Water

Dish or washing soap

Grey painters 3m scotch pad witch is equivalent to 800 wet and dry sand paper

1 pound of Citric Acid

Bi carb soad

WD- -40 / INOX / OR ANY MACHINE OIL

Gloves

Fill the container with water. The aprox ratio is 1 pond to 10 gals

Tho you can make it as strong or as week as you like. It wont hurt anything if you make it stronger. Now before dipping the item degrease it the best you can and strip all the paint off chemically is you intend to restore the whole item.

In same cases as with INDIAN MOTOCYCLE tanks the guys just want to have the Citric Acid eat all the rust on the inside of the tank while preserving the original INDIAN paint on the out side and this is fine.

Depending how rusted the object may be submerge the whole item completely. Every day lift it out and inspect the item and turn it around and give the brew a stir. After 3 days your item will become very grey and when you touch it you get grey residue on our hands that is hard to wash off. We will use a INDIAN MOTOCYCLE TANK FOR THE POURPOSE FOR EXPLANING THINGS. You will notice a grey residue. When you are happy that all the rust is gone then remove your tank and rinse it in BI – CARB SOAD to neutralize the CITRIC ACID.

Then get your Grey scotch pad that is fine like 800 wet and dry and with soapy water begin to rub down your tank and you will begin to remove the dark grey residue that was left. If there is any old skool re pairs of braze welding with bronze they will become very shiny like it has been polished….

BRAZE WELDING ADVANTAGE………….

This also has a another advantage…… BRONZE BRAZE WELDING with Nickel Bronze or Silicon Bronze leaves a very hard residue from the flux. It is so tuff it forms a crystal and not even cleaning it with a hi powered wire brush seems to remove it…….Tho the Citric Acid eats this flux and is a great way to remove it on an item that can be soaked.

The best part of this process is if you have a very rare INDIAN TANK an its been sitting for 60 years you can do all this with out compromising your original paint……. There is no need for gimmicks like using

POR 15 to clean you tank and use epoxy to seal the tank…… This is all B.S and it does not cost you $190 for the kit…..!!!

Citric Acid can be bought buy the pound and is very cheep unlike the dental bill you will get from your children eating candy……!!! LOL…………You will also discover that nearly all candy containing CITRIC ACID by law has to have BI – CARB SOADA as part of the candy. Next time you see sour candy and you crack it open you will find BI- CARB SOADA in the middle of the sour candy that is ment to eliminate the Acid while eating it……

There is no danger so the will be NO E.P.A hassle if you use this method and if you children lick it will just taste like sour candy to them.

So lets show you how a racing AJS motocycle tank turned out and 2 extremely RARE 1925 INDIAN PRINCE GAS TANKS TURNED OUT….!!! Both 1925 INDIAN MOTOCYCLE TANKS in very good condition can command $3500 each as they were one of the rarest and unique 1 model only tanks and bikes to be produced.

I had no concern for damaging such tanks as the process is very safe…..

After washing the tanks in boiling water and Bi – Carb soda the boiling water helps to heat the tin and as soon as you take it out of the water it instantly dries. Leaving something to dry can have the item ” FLASH RUST ” and becomes orange in several mints.

Once dry spray the item with oil of your choice. I prefer machine oil as it is a fine mineral oil that leaves only a small film on the tank…..!!!

You can put Citric Acid in a glass jar and put your nuts and bolts I it and they will come out like new…..Witch you can send to the zinc coater at a chrome shop..

If you do send your nuts and bolts to the chrome shop they will use CAUSTIC ACID to clean them first.. So you can save time and money by doing it your self and even zinc coating the parts at home with a kit……

There is also a second way to do the very same thing but is more expensive and a lot more messy. Using MOLLASSIS witch is a dark syrup when sugar cane is processed and is a by product. It is used on English toast and also given to horses as food and can be purchased at a feed shop.

This syrup can be watered down and be used in the exact same way as Citric Acid but takes a little longer and is smells a bit.

Using this method guarantees 100 % no damage to the integrity of your metal object and can be used on Motocycle frames , Fenders, Nut and bolts, And any metal parts you are using on your restoration. Cheep and cost effective and you will enjoy doing it your self……..

You can also dip parts you find that are rusty…. I took a cut off a car and its was very rusted but I wanted the part of the cut to weld into a project. After soaking it in Citric Acid it was all clean and ready to be braze welded into the project car.

I hope this helps every one else out there in correctly preserving the parts for there kustom car or motocycle.

KUSTOMLAND

PART 3 OF THE TUTORIAL WILL BE

” THE DILLON ENGLISH BRAZE WELDING GUN ”

YES IT LOOKS LIKE A HAND GUN….!!!!

July 27, 2017 at 09:20 #52384 Rik HovingKeymaster

Rik HovingKeymasterThe end result…

Enjoy the beauty of Customizing

July 28, 2017 at 11:09 #52397 Quentin HallParticipant

Quentin HallParticipantI’ve had similar results using phosphoric acid. You can buy concentrate about 20l makesa300 litres with added water. I soak whole doors and guards in a 1000ltr tank. This leaves a coating on the metal which protects the metal and stops rusting. But don’t use it on spring steel.

July 28, 2017 at 13:15 #52420 TonyParticipant

TonyParticipantPhosphoric acid is the active ingredient in molasses. In a state that grows a lot of sugar cane, it’s not hard to find!

I’ve used it many times.

For small things I’ve also had good results with 2l bottles of cheap supermarket vinegar.

July 28, 2017 at 13:27 #52421 Larry PointerParticipant

Larry PointerParticipantGail Hill at Ace Radiator in Sheridan, our Conquistadors’ big brother rest his soul, dipped fenders, doors and small parts for Neferteri in his large radiator cleaning vat. They all came out really clean. Except for old Bondo on the Dumbo ear front fenders. Much of it resisted removal.

For engine parts, some Montana guys are loosening rust and cleaning them up with apple cider vinegar, too. Pretty slow, but encouraging results.

-

AuthorPosts

- You must be logged in to reply to this topic.