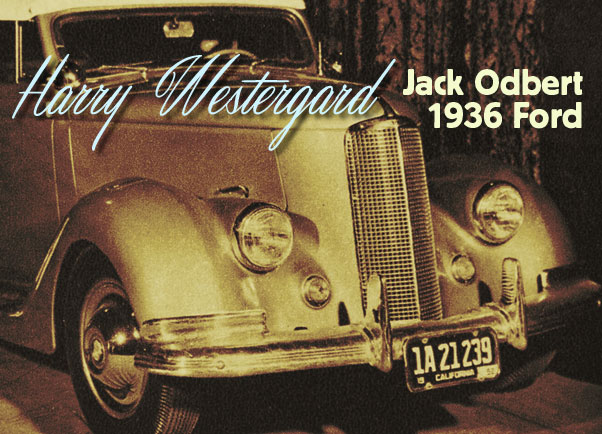

Dick Read’s Show Rod – How it was created

HOW IT WAS CREATED

In the first article on Dick Read’s Show Rod we showed you how the car looked liked when it was competing on the car-show circuit. In this second article we show you how Dick created the car.

In the first article we first asked the CCC-Readers if they knew anything about the current whereabouts of the car. Show car collector and Custom Car and Hot Rod enthusiast Mark Moriarity contacted us that he knew more about the car. He informed us that the car was still around, and that he would contact the current owner. Contact information was swapped and now the original builder and current owner have now been talking on the phone. Dick will soon be visiting the current owner in Michigan and for the first time since 1970 be able to see his old dream Show Rod in person again.

Dick built the car in Hoopeston, Illinois where he could use a corner at the Buick Pontiac dealership operated by Dick’s father. Dick was able to use all the tools from the dealer ship thru-out the build.

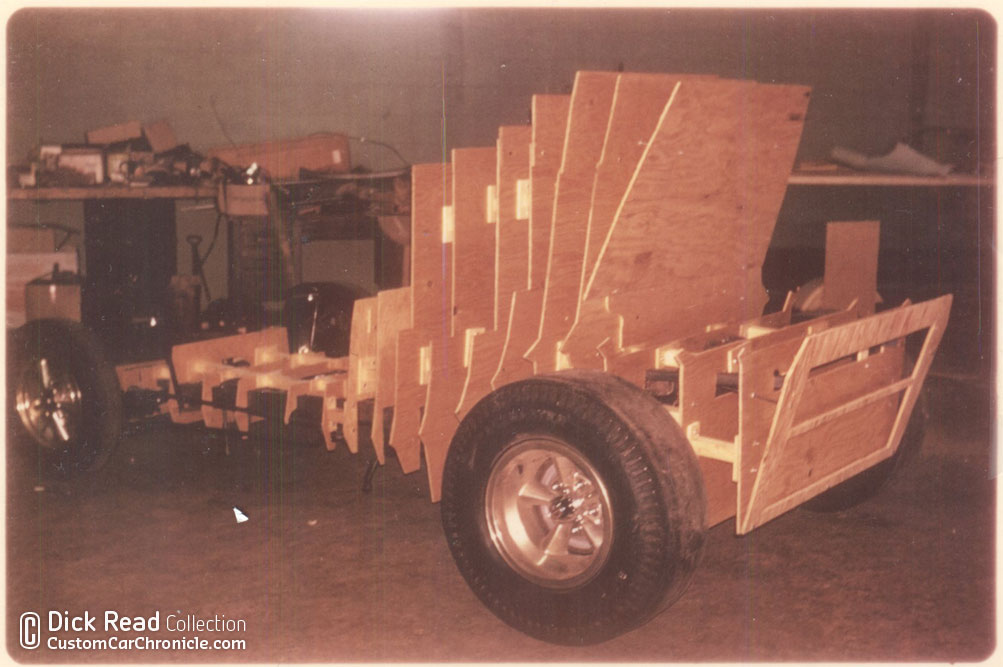

Several sketches were produced before the final design was picked. From there the first task was to create the frame and get the front and rear axle located. Once the wheels/tires could be mounted it was time to get the body shaped roughed in using plywood panels cut to shape.The more rounded section of the body design were bend up from metal tubing and welded together. Brackets were constructed to hold the tubing sections in place on the wood structure.

After the frame was constructed and the front and rear axle mounted it was time to construct the plywood frame on which the custom body could be shaped.

After the frame was constructed and the front and rear axle mounted it was time to construct the plywood frame on which the custom body could be shaped.

[divider]

Early construction photo show the angled plywood panels which created the base shape of the body.

Early construction photo show the angled plywood panels which created the base shape of the body.

[divider]

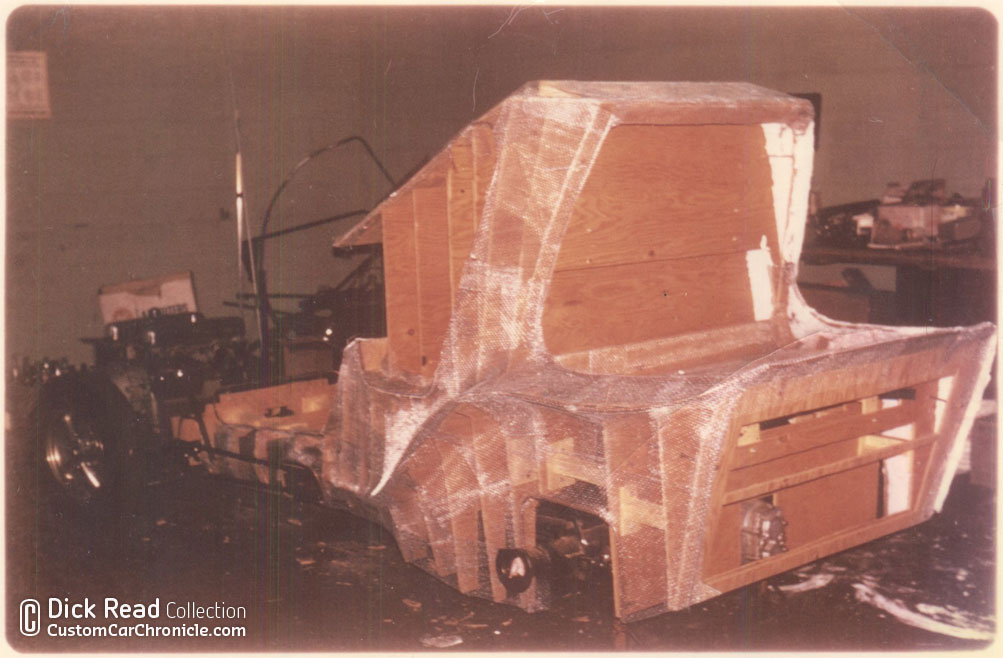

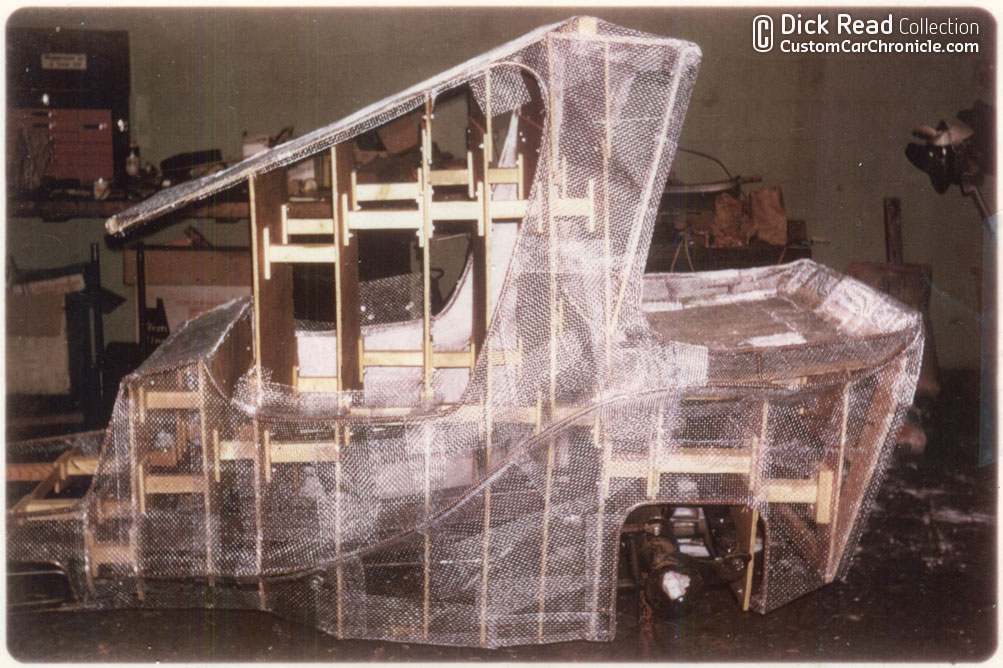

More plywood was added to use for the roof construction, and some of the round sections, like the fenders were shaped out of metal tubing. One the shape was perfect everything was covered with wire mesh.

More plywood was added to use for the roof construction, and some of the round sections, like the fenders were shaped out of metal tubing. One the shape was perfect everything was covered with wire mesh.

[divider]

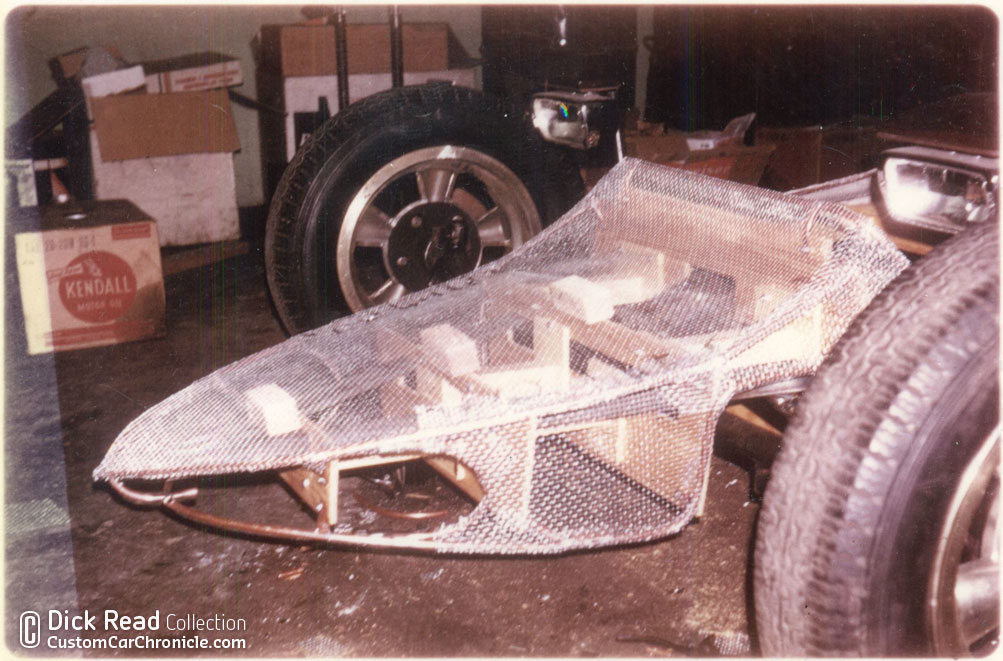

Most of the front end design was shaped from bended tubing which was welded to create the final shape. The metal rod construction was then attached to a wood base to hold it in place during the wire mesh shaping.

Most of the front end design was shaped from bended tubing which was welded to create the final shape. The metal rod construction was then attached to a wood base to hold it in place during the wire mesh shaping.

[divider]

This side view of the “cabin” gives a good view of the wire mesh shaped around the tubing and plywood. The whole structure is now taking shape and starting to look like the final car.

This side view of the “cabin” gives a good view of the wire mesh shaped around the tubing and plywood. The whole structure is now taking shape and starting to look like the final car.

[divider]

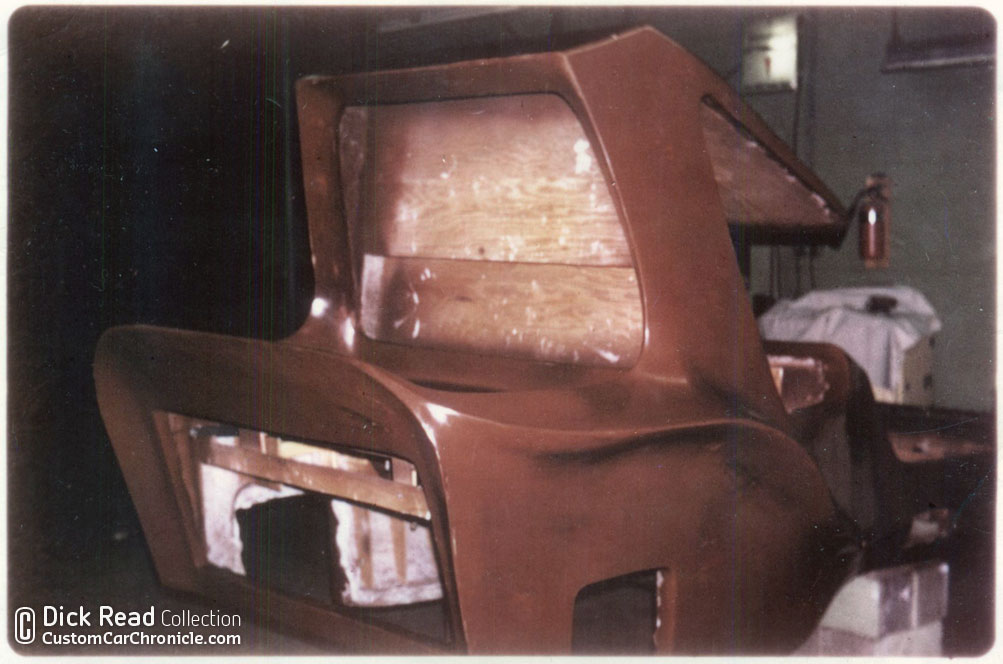

The wire mesh was then covered in plaster, and sanded smooth until Dick had created the perfect shape. Then everything was painted. The pattern or buck for creating the fiberglass body was now ready.

The wire mesh was then covered in plaster, and sanded smooth until Dick had created the perfect shape. Then everything was painted. The pattern or buck for creating the fiberglass body was now ready.

[divider]

The rear of the plaster over wire mesh base from the rear.

The rear of the plaster over wire mesh base from the rear.

[divider]

Next step was to cover the whole structure with fiberglass which would eventually act as a mold for creating the car’s body.

Next step was to cover the whole structure with fiberglass which would eventually act as a mold for creating the car’s body.

[divider]

After the fiberglass mold was created over the structure wood and metal rod were fiberglassed onto the mold. This would create an ultra strong mold. Which was needed since the plaster/wire mesh/wood/metal rod structure underneath it needed to be removed without damaging the mold. After this the fiberglass body will be laminated inside this mold.

After the fiberglass mold was created over the structure wood and metal rod were fiberglassed onto the mold. This would create an ultra strong mold. Which was needed since the plaster/wire mesh/wood/metal rod structure underneath it needed to be removed without damaging the mold. After this the fiberglass body will be laminated inside this mold.

You can see the result in the third article on Dick Read’s Show Rod.

[divider]

[divider]

(this article is sponsored by)

![]()