Chop-A-Top

CHOP-A-TOP

Chop-A-Top, is the photo essay narrative for Ron Tesinsky’s documentation of the steps he took in chopping Gerald Brantz’s 1950 Mercury.

By Larry Pointer, 1987 photos by Ron Tesinsky

Sheridan, Wyoming Conquistador Gerald Brantz chose to take his restored 50 Mercury to Ron Tesinsky at West Side Kustoms outside Billings, Montana for further work. In taking this nicely restored coupe into that otherworldly realm of the full custom, Tesinsky first addressed Brantz’s request for a full, but well-balanced top chop. Ever a meticulous craftsman, Ron documented each and every step in photographs. Ron chopped the top on Gerald’s Mercury back in 1987.

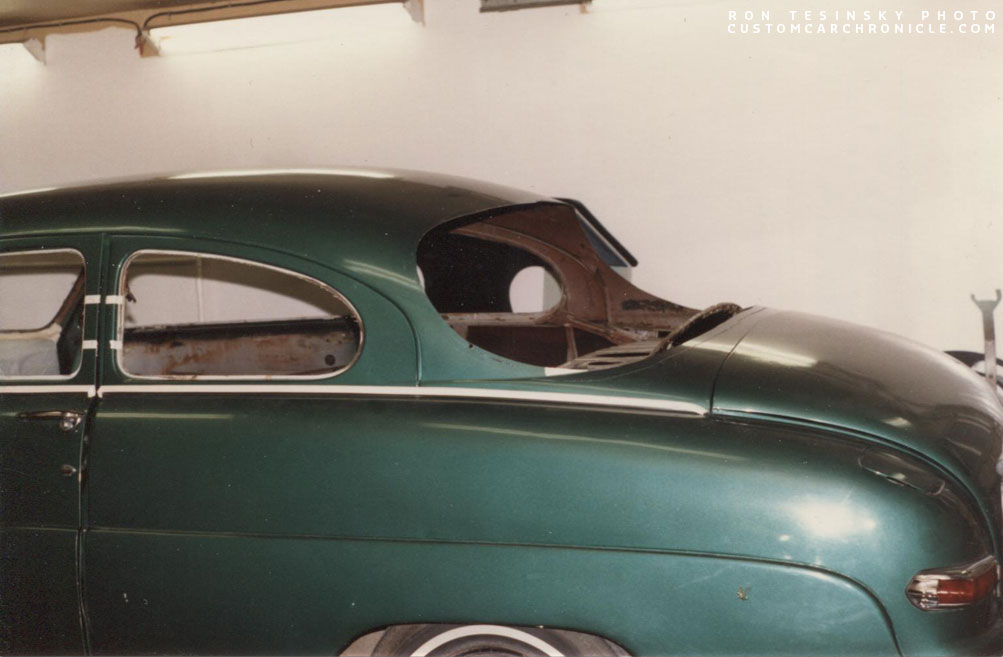

To prepare the car for surgery, he removed window glass, garnish moldings, headliner and upholstery.

To prepare the car for surgery, he removed window glass, garnish moldings, headliner and upholstery.

[divider]

Carefully, he cut away the rear window, intact with an ample surround of metal.

Carefully, he cut away the rear window, intact with an ample surround of metal.

[divider]

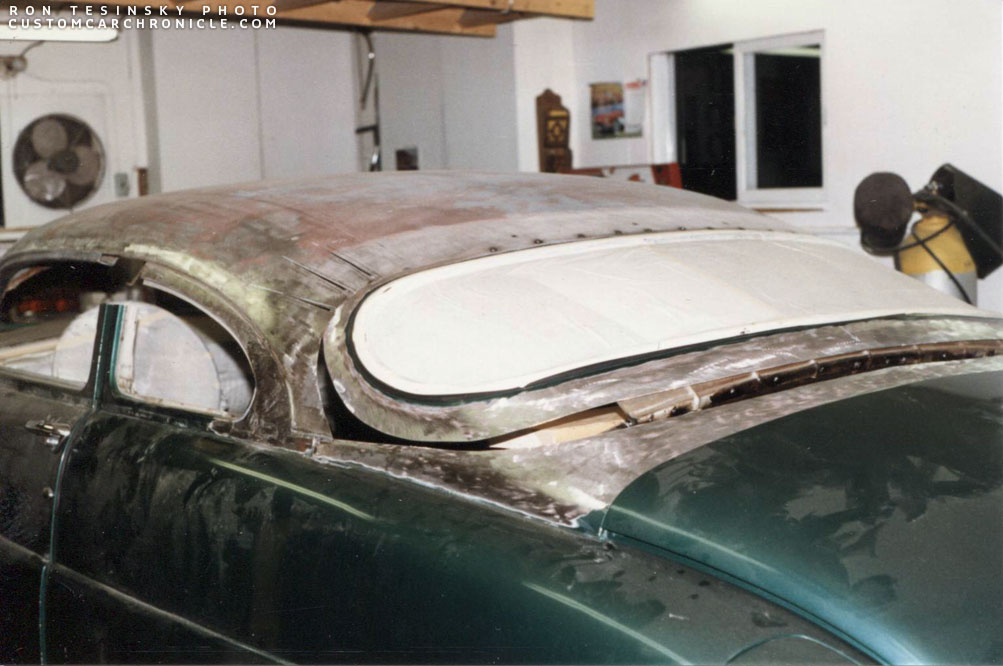

The rear window, then, was protected with thick paper stock, and set safely aside.

The rear window, then, was protected with thick paper stock, and set safely aside.

[divider]

Each pillar in support of the roof was marked in preparation for the cuts that would follow. A pair of tape lines were laid down, 3 ½ inches vertically apart. The same was done for the tops of the doors. The top then was detached along the line of the upper taped lines, lifted off and set aside. The same was done for the doors.

Each pillar in support of the roof was marked in preparation for the cuts that would follow. A pair of tape lines were laid down, 3 ½ inches vertically apart. The same was done for the tops of the doors. The top then was detached along the line of the upper taped lines, lifted off and set aside. The same was done for the doors.

[divider]

Next, the A-pillars were cut along the bottom tape mark, and the roof panel was lifted onto the car and aligned at the A pillars. Material was removed from the C pillars until the rear of the top dropped to the desired profile. This resulted in the top being slid forward, in compensation for the 3 ½ inch drop in elevation. Like a cone cut in the middle, the flow of taper no longer matched, top to bottom, front to back.

Next, the A-pillars were cut along the bottom tape mark, and the roof panel was lifted onto the car and aligned at the A pillars. Material was removed from the C pillars until the rear of the top dropped to the desired profile. This resulted in the top being slid forward, in compensation for the 3 ½ inch drop in elevation. Like a cone cut in the middle, the flow of taper no longer matched, top to bottom, front to back.

[divider]

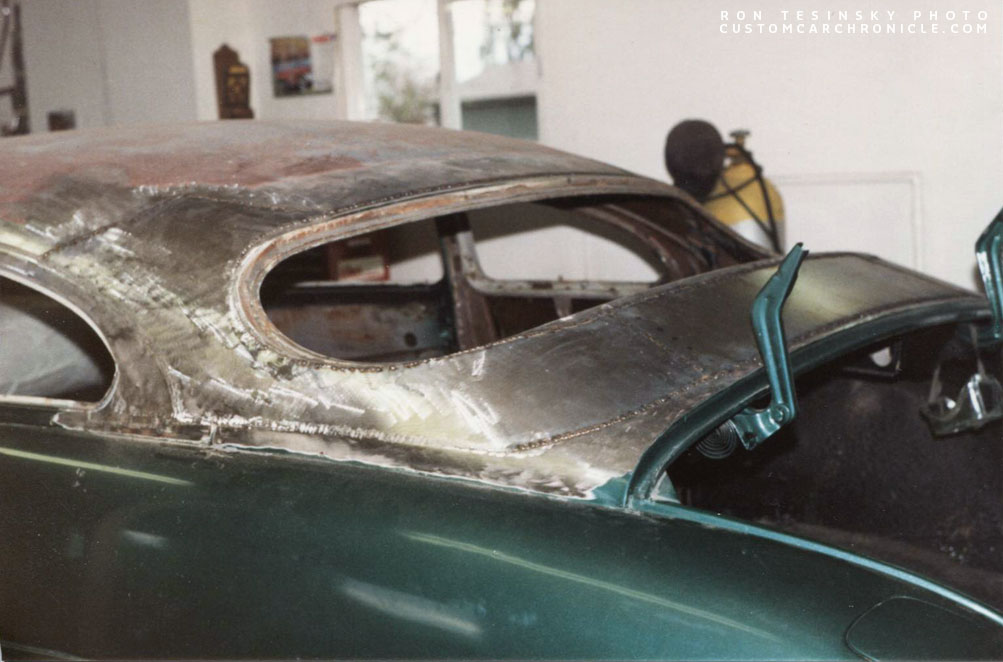

View from the back. The top portion of the B pillars (the pillar stubs) up to the drip rail, has been removed completely at this point.

View from the back. The top portion of the B pillars (the pillar stubs) up to the drip rail, has been removed completely at this point.

[divider]

Another result of the forward placement of the roof panel was that the B pillars of the roof section now were too far forward to realign with the base of the B pillars on the car. Carefully measuring out a calculated distance forward and rearward from the roof’s hanging B post, Ron cut the pillar stub out of the roof panel.

At the rear of the quarter window opening, Ron re-formed a smooth, tight, curve into the attachment of car body with roof panel. The separated roof section containing the rear window now could be tacked into its new home. This, however, also required some adjustments. The sloping curve of the main roof panel, along each side down to the replaced rear window piece, now also did not align. To create a smooth transition curve in these areas, Ron made a series of slits up into the main roof panel, at each side above the rear window piece. This then allowed him to re-splice these compound curves into a pleasing flow of curvature down to the rear window.

At the rear of the quarter window opening, Ron re-formed a smooth, tight, curve into the attachment of car body with roof panel. The separated roof section containing the rear window now could be tacked into its new home. This, however, also required some adjustments. The sloping curve of the main roof panel, along each side down to the replaced rear window piece, now also did not align. To create a smooth transition curve in these areas, Ron made a series of slits up into the main roof panel, at each side above the rear window piece. This then allowed him to re-splice these compound curves into a pleasing flow of curvature down to the rear window.

[divider]

This surgery trick, however, only goes so far in dealing with the disruption of the compound curvature of the bulbous Mercury roof, Ron pointed out. The rear sail panels presented a much more complicated problem in geometry. To solve this dilemma, Ron made a set of templates, right and left, and adjusted their shapes until he was pleased with the flow of these critical roof sections. At this point, he transferred the outline of each template onto fresh 20 gauge sheet metal.

This surgery trick, however, only goes so far in dealing with the disruption of the compound curvature of the bulbous Mercury roof, Ron pointed out. The rear sail panels presented a much more complicated problem in geometry. To solve this dilemma, Ron made a set of templates, right and left, and adjusted their shapes until he was pleased with the flow of these critical roof sections. At this point, he transferred the outline of each template onto fresh 20 gauge sheet metal.

[divider]

The sheet metal then was shaped with an English wheel, Ron deftly working curvature into the metal until each laid smoothly and integrally into position.

The sheet metal then was shaped with an English wheel, Ron deftly working curvature into the metal until each laid smoothly and integrally into position.

[divider]

Between the two new sail panels, a new center piece was cut and shaped to join them below the rear window. Now the chopped top flowed smoothly into the deck lid surround.

Between the two new sail panels, a new center piece was cut and shaped to join them below the rear window. Now the chopped top flowed smoothly into the deck lid surround.

[divider]

Sliding these post pieces forward into alignment with the post stubs on the car body, Ron then reattached the two segments together, re-creating the original vertical alignment of the B pillar. Others have taken a different approach at this point, slanting the B pillar forward to compensate for the unavoidable roof offset, and slicing pie-shaped pieces out of the corners to effect a smooth forward slant. Ron, in this case, chose to keep the original vertical alignment intact. The resulting gap in the roof panel below the drip rail, forward of the realigned post, then was filled with a patch taken from material removed in the previous step.

The top of the B pillars are now in place, time to do the door tops.

The top of the B pillars are now in place, time to do the door tops.

[divider]

The top pieces of the door frames were reattached in their chopped configuration, then the top rear corners of the doors were rounded. This same curve then was done in complementary fashion to the forward section of the top of the B pillar.

The top pieces of the door frames were reattached in their chopped configuration, then the top rear corners of the doors were rounded. This same curve then was done in complementary fashion to the forward section of the top of the B pillar.

[divider]

It was decided to completely remove the drip rails from the car. In their place, Ron later shaped a sculpted line of 3/8 inch rod. At the rear of the roof, however, instead of the abrupt stock Mercury drop of the drip rail down to the beltline, Ron carried the sculpted line rearward in a gentle bell-shaped curve taper. This is one of the most striking custom touches to this example of what otherwise might be considered a pretty standard chop to a Mercury top.

It was decided to completely remove the drip rails from the car. In their place, Ron later shaped a sculpted line of 3/8 inch rod. At the rear of the roof, however, instead of the abrupt stock Mercury drop of the drip rail down to the beltline, Ron carried the sculpted line rearward in a gentle bell-shaped curve taper. This is one of the most striking custom touches to this example of what otherwise might be considered a pretty standard chop to a Mercury top.

[divider]

A look inside with reworked brackets, next up are cutting up and reshaping garnish moldings to fit the lower and reshaped window openings.

A look inside with reworked brackets, next up are cutting up and reshaping garnish moldings to fit the lower and reshaped window openings.

[divider]

Garnish moldings for doors, quarter windows and windshield now were chopped and refitted into the interior of the new vertically smaller window openings.

Garnish moldings for doors, quarter windows and windshield now were chopped and refitted into the interior of the new vertically smaller window openings.

[divider]

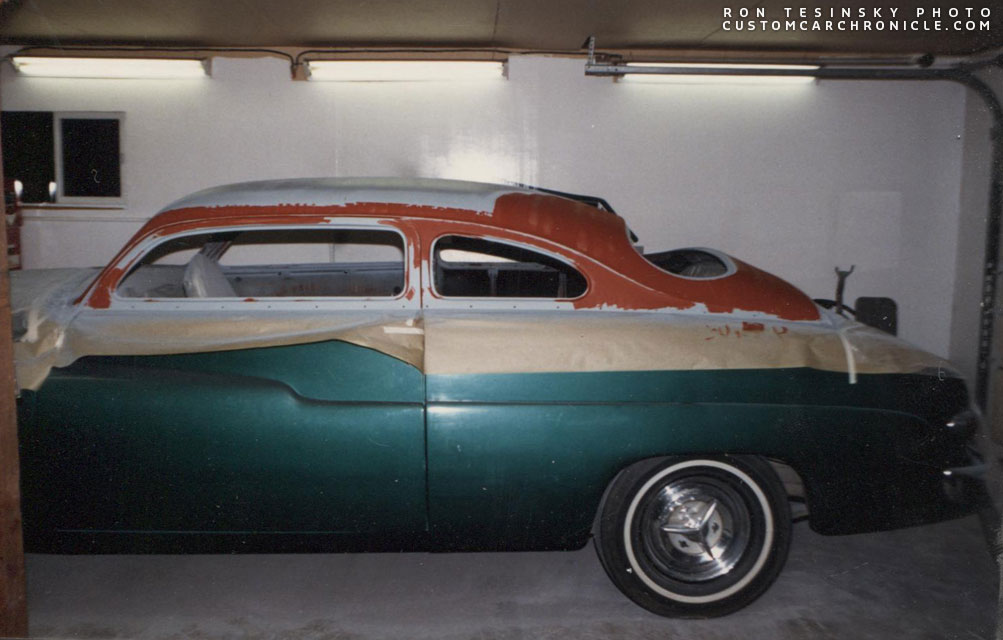

With all the metal work done and checked outside to make sure everything was as planned Ron started to prep the body for filler and primer.

With all the metal work done and checked outside to make sure everything was as planned Ron started to prep the body for filler and primer.

[divider]

Ron is a believer in the new (1980’s) epoxy and polyurethane filler products on the market. They are much more flexible than that old hard Bondo that first came onto the market back in the day. Given that neither lead nor filler lasts forever, Ron weighs in on the side of safety and ease of application of the new fillers.

Ron is a believer in the new (1980’s) epoxy and polyurethane filler products on the market. They are much more flexible than that old hard Bondo that first came onto the market back in the day. Given that neither lead nor filler lasts forever, Ron weighs in on the side of safety and ease of application of the new fillers.

[divider]

As to trimming out the top, Ron offered this bit of caution. For exterior trim around the quarter windows, he had secured some aftermarket “chrome” material, instead of trying to silver solder or reform stainless trim. That material hasn’t held up well, especially if a car is subjected to the elements over time.

As to trimming out the top, Ron offered this bit of caution. For exterior trim around the quarter windows, he had secured some aftermarket “chrome” material, instead of trying to silver solder or reform stainless trim. That material hasn’t held up well, especially if a car is subjected to the elements over time.

[divider]

Once Tesinsky had achieved the smooth curvatures he was seeking, he shot the work areas in epoxy primer, fitted new glass in the car’s altered openings, and installed window trim.

Once Tesinsky had achieved the smooth curvatures he was seeking, he shot the work areas in epoxy primer, fitted new glass in the car’s altered openings, and installed window trim.

[divider]

At this point, work was temporarily halted, and the car returned to Gerald Brantz. Gerald epoxy primered the complete car and made it ready for some serious cruising prior to subsequent phases in the evolution of this remarkable 1962-period-perfect custom 1950 Mercury.

More progress on Gerald’s 1950 Mercury Custom will follow soon in part 2.

The Mercury after the black epoxy primer was added. Gerald drove the car around for some time before taking it apart for phase two, “the Shadow”.

The Mercury after the black epoxy primer was added. Gerald drove the car around for some time before taking it apart for phase two, “the Shadow”.

[divider]

(this article is sponsored by)

![]()

Nice story and good pictures from start to finish. I like the flow of the rear of the top and the attention to detail.

Excellent spotlight on a local favorite. What a perfectly done and detailed chop. Great article!