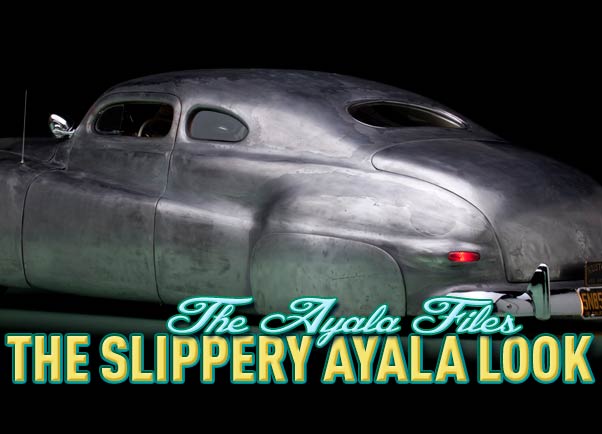

The Slippery Ayala Look

SLIPPERY AYALA LOOK

Gil and Al Ayala started creating Custom Cars in around 1945. One of their trademark restyling techniques would become the super smooth molded in everything look. The Slippery Ayala Look.

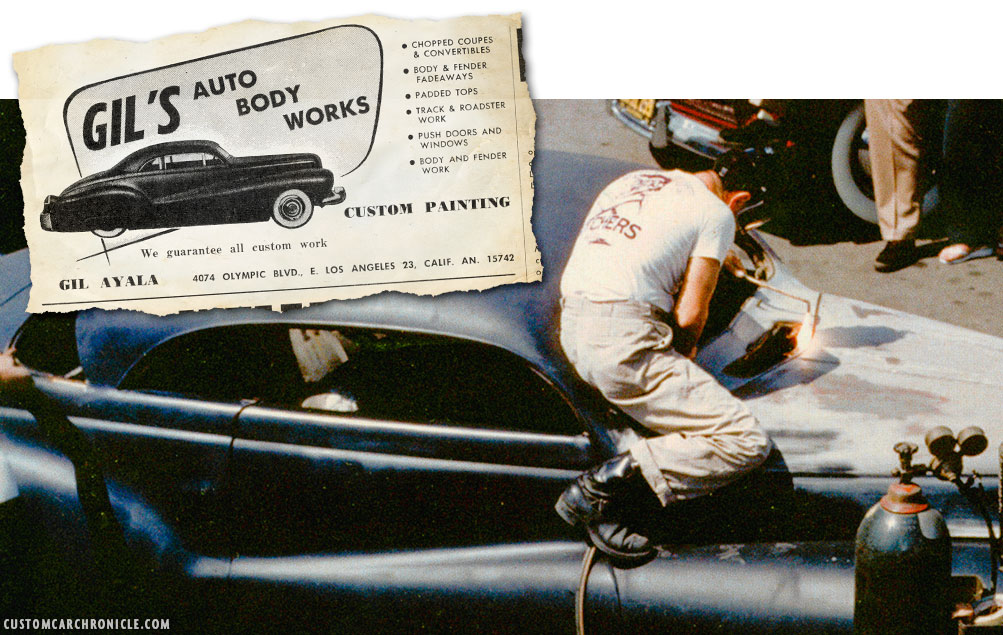

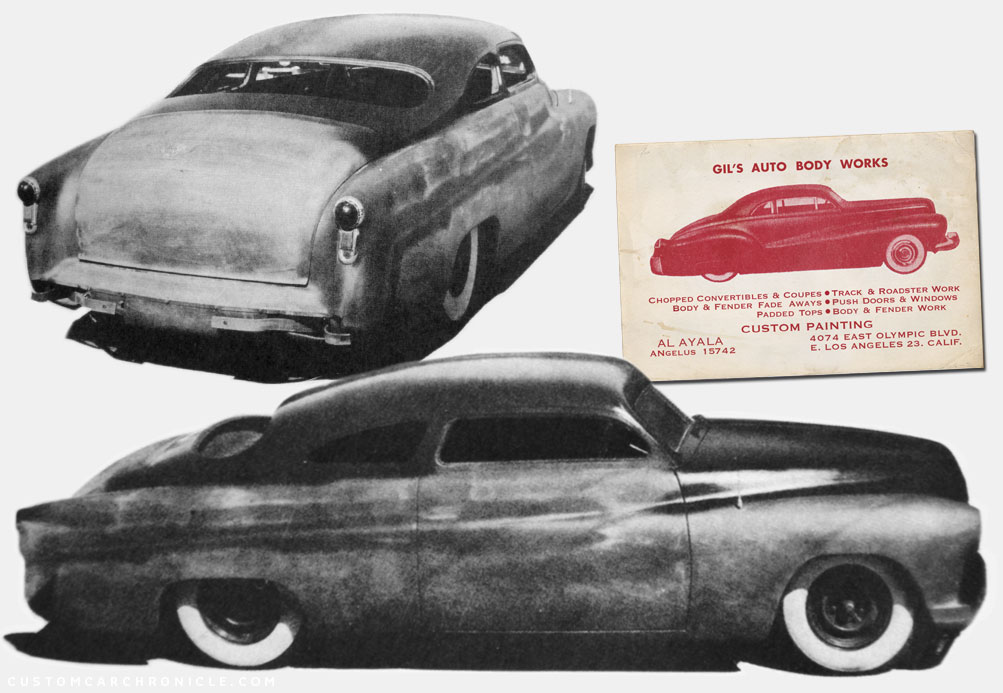

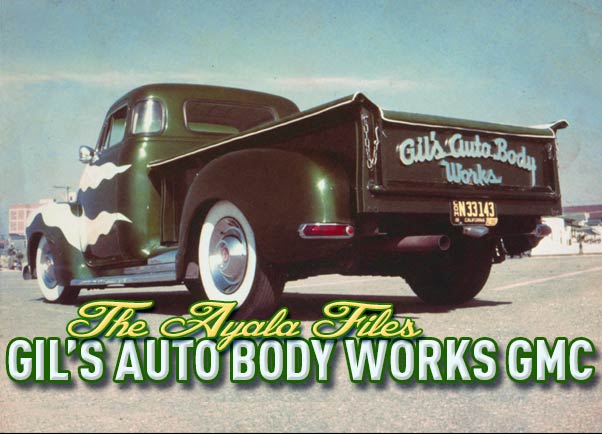

In 1945 Gil Ayala opened his Gil’s Auto Body Works shop on 4074 East Olympic Boulevard in East Los Angeles. Together with his older brother Al Ayala an several part-time employees the shop would turn out truly unique and trend setting Custom Cars for several decades.

Each of the famous and well known body-shops from the 1940s and 1950’s had some sort of signature look, a look that you could easily recognize. When you saw a car created by one of these particular shops, you were able to identify it because of this signature look, often a combination of the shops specialities. The Valley Custom Shop from Burbank Ca, was known for their factory Custom look, and especially for their subtile sharp looking body work and sectioned bodies. The Barris shop in Lynwood was easily recognizable from their wonderful balanced restyled and chopped cars with the right amount of unique side trim- and grill designs, and mile-deep organic paint jobs (and from 1952 on of course from the Barris Crest).

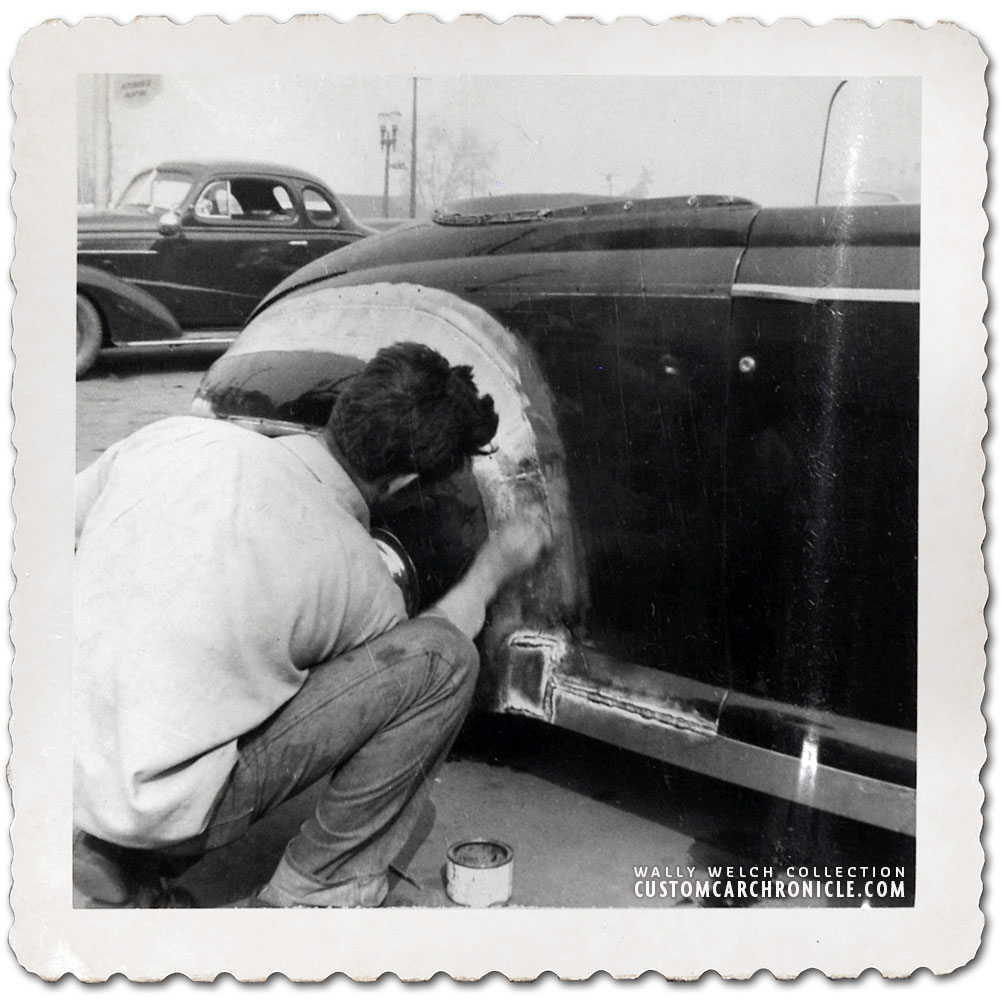

Al Ayala working on the cowl vent of the Ayala 1940 Mercury.

Al Ayala working on the cowl vent of the Ayala 1940 Mercury.

[divider]

The Ayala’s where best known for a few things, full fade-away fenders, very creative brilliant home mixed paint and most important their ultra smooth, slippery one piece streamlined bodies with absence of most of the body trim pieces. Both Al and Gil Ayala worked together when it came to the designing of the cars, but it was Al who loved to blend-in panels using hand shaped and pre-shaped panels, everything needed for that wonderful one piece molten-butter-streamline-look. Al was responsible for most of the body-work done in the shop. It takes great design skills to be able to pull this style off, Remove all the trim pieces that helped guide the eyes, and still make a car look very attractive and interesting. This super smooth body style was very popular in the late 1940’s and early 1950’s. There are plenty of samples of similar molded in customs from back in the day or even recently created customs that have all the elements, but are still not working like those old Ayala Customs.

Even though the Slippery Smooth style was something typically Ayala, that did not mean that very car done by the Ayala’s had this look. I guess the majority of the cars they created did not have this special look. Mostly because it was very time consuming, and very costly, so it was up to what project came to the shop, and how much money the owner was willing to spend. Also several other shops around the 48-54 time frame used similar styling, the Barris Kustoms built Snooky Janich ’41 Ford business Coupe and the Hirohata Merc for instance are good sample of a similar smooth look.

The brothers Gil and Al Ayala just had the eye for doing this style and with a few sample cars shown in this article. I will show what was important to make this style work so well.

- Wally Welch 1941 Ford

- Gil Ayala 1940 Mercury

- Jack stewart 1941 Ford

- Hank griffith 1942 Ford

- Gil Ayala 1942 Ford

- Louis Betancourt 1949 Mercury

- Buddy Alcorn Mercury

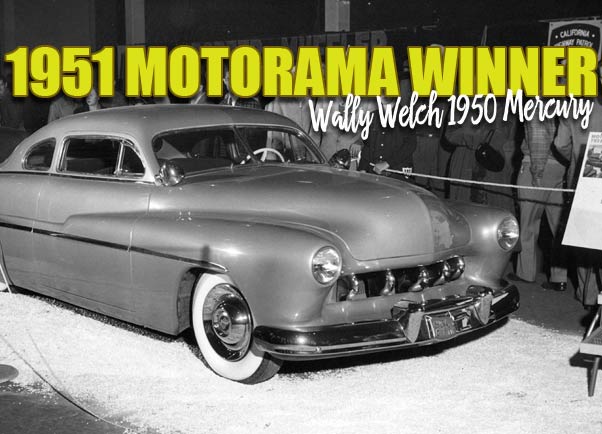

Wally Welch 1941 Ford

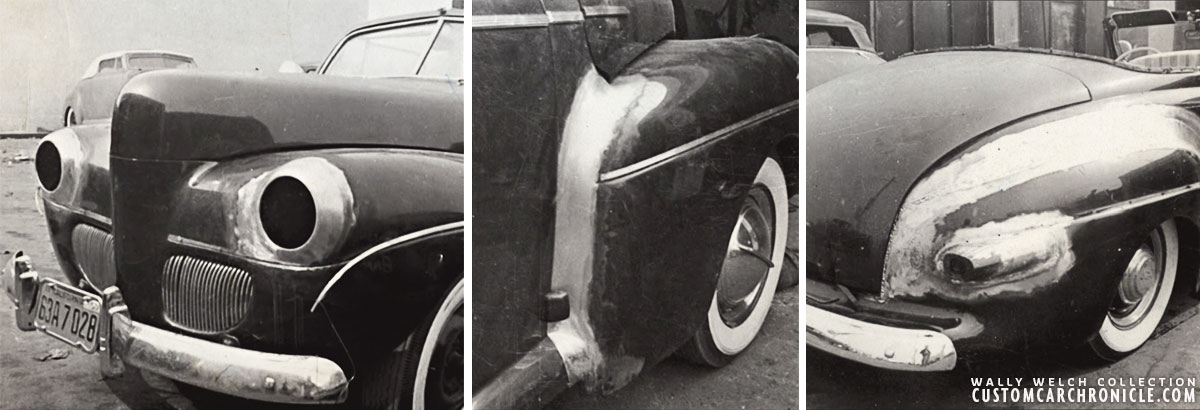

I like to start with the Wally Welch ’41 Ford, not because it was the first one done, it was not, but just because at this moment it is the only car we have nice and clear in-progress photos of how the Ayala’s created this smooth look. These photos clearly show that the majority of the shaping, the smoothing of the body lines was done using pre-shaped metal panels, and only a limited amount of lead was used. There are also sampled were a larger amount of lead was used to fill in the smoothed panels. And even some other photos show that all of the smoothing was done done with lead, and no metal shaping was used. We are not sure why different techniques were used for this. Perhaps it was a time/money thing where the use of lead was easier, quicker, thus less expensive, but that is only a guess. The Wally Welch ’41 Ford is still using some exterior trim, so it might be seen as only a partial Slippery Ayala Look, but the progress photos sure help us understand how Gil and Al created their characteristic Custom Look.

1949 The Ayala’s mold the rear fenders on Wally Welch’s 1941 Ford convertible. The work is done by hand or pre-shaped metal strips that follow the contour of the fender, and have a nice radius to make the fender flow smoothly into the rest of the body. The work was most likely performed by Al Ayala who performed the majority of the body work at the shop.

1949 The Ayala’s mold the rear fenders on Wally Welch’s 1941 Ford convertible. The work is done by hand or pre-shaped metal strips that follow the contour of the fender, and have a nice radius to make the fender flow smoothly into the rest of the body. The work was most likely performed by Al Ayala who performed the majority of the body work at the shop.

[divider]

Cleaning the fresh metal work so that the lead will stick to it.

Cleaning the fresh metal work so that the lead will stick to it.

[divider]

Lead was carefully added for the ultimate smooth molded fender look.

Lead was carefully added for the ultimate smooth molded fender look.

[divider]

The headlights and front fenders also get the smooth look. Wally’s Ford still had some trim on the body left, it is not the the super smooth Ayala look, but these photos give us a good look how the Ayala’s created the Slippery Smooth Look.

The headlights and front fenders also get the smooth look. Wally’s Ford still had some trim on the body left, it is not the the super smooth Ayala look, but these photos give us a good look how the Ayala’s created the Slippery Smooth Look.

[divider]

The California Metal Shaping Company supplied many pre-shaped metal panels to the Ayala’s. The CMS shop was equipped with far better machined that could create the shaped panels needed for the Ayala smooth streamline look much faster than Al Ayala could do in the Ayala shop. The shop was located at 1704 Hooper Ave in Los Angeles.

The California Metal Shaping Company supplied many pre-shaped metal panels to the Ayala’s. The CMS shop was equipped with far better machined that could create the shaped panels needed for the Ayala smooth streamline look much faster than Al Ayala could do in the Ayala shop. The shop was located at 1704 Hooper Ave in Los Angeles.

[divider]

Gil Ayala 1940 Mercury

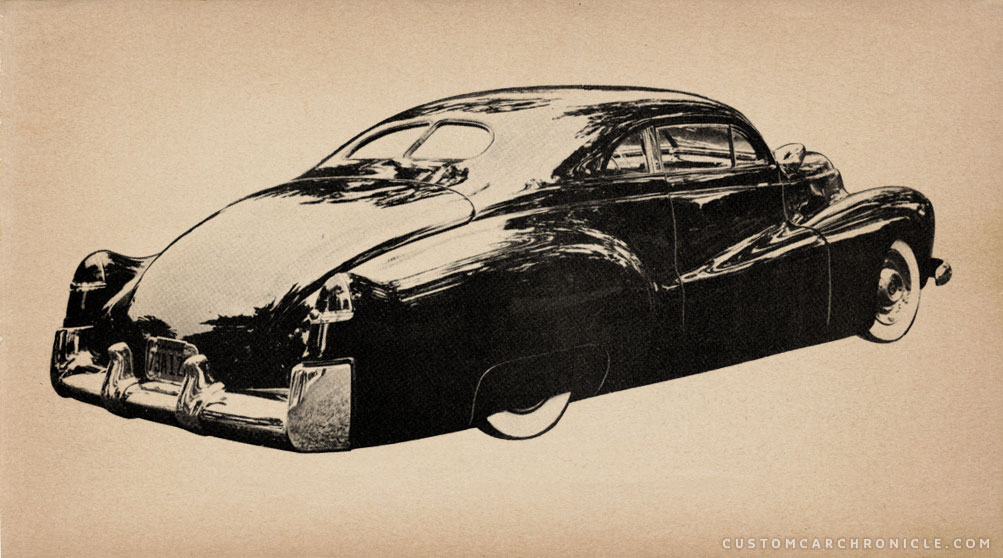

Gil Ayala’s 1940 Mercury with ’48 Cadillac rear fenders is a perfect sample of the Slippery Ayala Look. Most of the exterior trim has been removed from the car, except the windshield and side window trim as well as the taillight trim and grille. All the handles were removed holes filled and everything was smoothed. But the major part of the Ayala look comes from the molded in Cadillac rear fenders and the full fade away front fenders with molded in headlights. The fade away fenders were welded to the body, and the line from the fenders to the body was molded with a nice flowing radius, very similar in look and feel as the round shapes found elsewhere on the car.

On factory stock cars with fade away fenders, like the 42-48 Buicks the fade away fenders are usually bold on parts, with a sharp edge from fender to body. The Ayala’s decided that that look would not fit their Customs, so the fender extensions, most likely shaped by the California Metal Shaping company were welded to the body, and flared with a large amount of lead, or perhaps with shaped metal panels.

The front 3/4 view shows the flowing radius on the molded in fade away fenders really well. It also shows that it was necessary to create a dip in the radius section at the front of the door, allowing the door to be opening inside the front portion of the fade away fenders.

The front 3/4 view shows the flowing radius on the molded in fade away fenders really well. It also shows that it was necessary to create a dip in the radius section at the front of the door, allowing the door to be opening inside the front portion of the fade away fenders.

[divider]

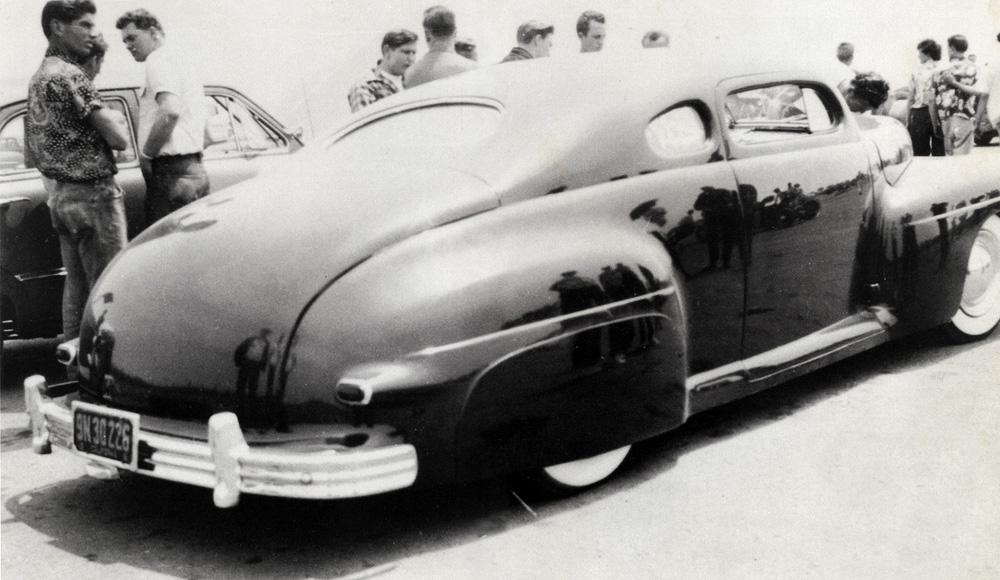

Slippery Smooth rear 3/4 view.

Slippery Smooth rear 3/4 view.

[divider]

Jack Stewart 1941 Ford

The Jack Stewart Ford is I think the second best sample (following the first versions of the Louis Bettancourt ’49 Mercury) of the Ayala Slippery Smooth look. And second best is only because some of the details on the car were later restyled by George Barris, so this one is not 100% pure Ayala.

This Custom was started in 1948 by Jack Stewart and a friend, but in 1949 Jack took it to the Ayala’s to take it to the next level. Al and Gil Ayala re-chopped the top to make it flow much better, they created full fade-away fenders and a new hood. Then everything was molded into one piece, using shaped metal and blended together with lead.

Jack Stewart’s ’41 Ford at Gil’s Auto Body Works around 1949. Most of the work on the car was done by then. Later George Barris would reshape the taillights and clean up the fender character lines. But the whole slippery smooth lines of the car originate at the Ayala shop.

Jack Stewart’s ’41 Ford at Gil’s Auto Body Works around 1949. Most of the work on the car was done by then. Later George Barris would reshape the taillights and clean up the fender character lines. But the whole slippery smooth lines of the car originate at the Ayala shop.

[divider]

The Ayalas used the California Metal Shaping company pre-shaped panels that where created from Al’s instructions. This way the shop saved a lot of time creating the wonderful smooth molded look. One of the features of the Smoothed Ayala look is the lack of body chrome. On the Jack Stewart Ford only the bumpers, grille, windshield molding, Appleton Spots and vent window divider are chrome or stainless. Still Al was able to create a unique body shape that your eye would follow from the front all the way to the rear bumper. The Ayala’s where brilliant in finding just the right radius of molding in the parts. Combined with a flow of the top, and heavily reshaped window openings they were able to create very interesting flowing and streamlined lines on a one piece looking body. Of big help to this look are rounded corners on the hood, door corners and trunk. These corners were not just rounded, the right radius was carefully figured out comparing to other body elements and amount of flow needed.

The Jack Stewart Ford in 1951, shortly after Jim Skonzakes had bought it from Jack Stewart and drove it from Los Angeles to Dayton Ohio, where Jim lived. The rear quarter view shows that the only sharp edges on the car are from the opening or removable body panel, everything else has been molded and smoothed.

The Jack Stewart Ford in 1951, shortly after Jim Skonzakes had bought it from Jack Stewart and drove it from Los Angeles to Dayton Ohio, where Jim lived. The rear quarter view shows that the only sharp edges on the car are from the opening or removable body panel, everything else has been molded and smoothed.

[divider]

An interesting detail is that when the Ayala’s created the car around 1949 they used a molded taillight pod with 46-48 Ford taillights, similar to those used on the Wally Welch Ford, as well as Gil’s personal ’42 Ford. It was George Barris who reshaped those taillights to fit more with the Ayala Slippery body contours. And it makes me wonder if George Barris and his brother Sam perhaps got inspired by these melting butter smooth look and might have used it later on the Janich and Hirohata customs.

The best thing about the Jack Stewart Ford is that car has survived and is now owned by Palle Johansen from Denmark. During its restoration the car has been stripped to bare metal and we are now able to show in detail how the super smooth Ayala look was created.

During the restoration of the Jack Stewart Ford the door jam panel of the fade away fender section had to be cut off to fix some rust, and be able to get a better fitting door. This allows us to see how the California Metal Shaping panel was created, and how the Ayala’s had molded it to the ’41 Ford doors. In contrast with the molded in fenders on the Wally Welch Mercury, this radius was done completely with lead.

During the restoration of the Jack Stewart Ford the door jam panel of the fade away fender section had to be cut off to fix some rust, and be able to get a better fitting door. This allows us to see how the California Metal Shaping panel was created, and how the Ayala’s had molded it to the ’41 Ford doors. In contrast with the molded in fenders on the Wally Welch Mercury, this radius was done completely with lead.

[divider]

Rear 3/4 view of the Jack Stewart Ford in bare metal shows that the Ayala’s, and later George Barris smoothed reshaped the metal during the restyling and smoothed everything out with lead The moulded belt line is clearly visible in this photo. The finishing touch was a set of hand made taillights created by Bob Hirohata.

Rear 3/4 view of the Jack Stewart Ford in bare metal shows that the Ayala’s, and later George Barris smoothed reshaped the metal during the restyling and smoothed everything out with lead The moulded belt line is clearly visible in this photo. The finishing touch was a set of hand made taillights created by Bob Hirohata.

[divider]

The side view shows the molded rear fenders, fade away fenders and the smoothed beltline. Even with all this round molded body work, the Ayala’d were able to maintain an interesting looking car that flows from front to rear seamingly in motion while standing still.

The side view shows the molded rear fenders, fade away fenders and the smoothed beltline. Even with all this round molded body work, the Ayala’d were able to maintain an interesting looking car that flows from front to rear seamingly in motion while standing still.

[divider]

The rear quarter view makes the car look like it was carved from soft wax.

The rear quarter view makes the car look like it was carved from soft wax.

[divider]

Hank griffith 1942 Ford

Hank Griffith‘s 1942 Ford is an interesting car in many ways, but especially when it comes to the Ayala Smooth Look. The car was actually only partly built at the Ayala shop, and the work they performed was done with the typical Ayala look, while the rest of the restyling was done in a more conventional style. When Hank took his Ford to the Ayala’s he already had his good friend Ray Saconi chop the top on the coupe. A straightforward chop with the drip rails left in place,while those were about the first thing to go when the Ayala’s would chop a top. But since the chop was already done, it was left alone and the Ayala’s were asked to integrate a set of 1950 Cadillac rear fenders and doors (for the fade aways) as well as the grille into the ’42 Ford.

The stock Ford rear fenders were removed and the Caddy rear fenders modified to fit the Ford body. Especially at the front the fenders needed some work to work with the ’42 Ford body. The fenders were welded in place and leaded smooth into the body. The front fenders were extended at the rear and the Cadillac doors used to create the fade away panels all the way to the back of the door where they meet the reshaped front section of the rear fenders. The new rear fenders ended at the rear door jamb. The headights rings were frenched into the front feders and the grille opening reshaped to fir the Cadillac grille. The new sides of the ’41 Ford have now been totally Ayala reshaped. with a nice flowing and smooth feel, which is now actually a huge contrast with the bit square chopped top with sharp drip rails. Hank later had the car repainted in a deep root-beer color.

This low angle view of Hank Griffit’s ’42 Ford shows the nice and smooth flowing work on the fenders and body sides, compared to the square chopped top. It makes me wonder if the Ayala’s ever got tempted toe reshow the top with more flowing and smoother lines during the time the car was at their shop.

This low angle view of Hank Griffit’s ’42 Ford shows the nice and smooth flowing work on the fenders and body sides, compared to the square chopped top. It makes me wonder if the Ayala’s ever got tempted toe reshow the top with more flowing and smoother lines during the time the car was at their shop.

[divider]

Removing the drip rails

The removed drip-rails is one of the important features of this Ayala look. The Ayala’s were not the only shop to do that, but they sure were extremely good at it. Most of the cars they created with shaved drip rails had the side window openings and door tops reshaped to work better with the new smooth look. However the first time the shop decided to shave the drip-rails on a car, it was not done pure as a design element, it started out as a practical thing.

Custom car legend Memo Ortega, who owned Gil Ayala’s personal 1946 Ford in the late 1950 remembered that he asked Gil about the shaved drip rails in the early 1950’s. Gil mentioned that the first time they shaved the drip rails it was done to save time, and do the job cheaper for the client. The client loved the fully shaved look, as well as the lower bill. The shaved drip rail look was noticed by new clients and a trend was set. The Ayala’s were very good in chopping tops this way. Often extending the rear quarter windows a bit more than when the same chop was made with the drip rails still in place. Also the flow from the door opening to the rear quarter window had to be dealt with very carefully. The drip rail was a practical element, but it also helped the eye with the flow of the car. Without this extra line the flow of the door and side windows needed to be just right, and that was what the Ayala’s were capable of creating.

Gil Ayala 1942 Ford

Personal cars from a Custom Body Shop are more than just a project, they are the shops business card, a rolling advertisement for the skills available in the shop. Personal cars were created for fun, for sure, but also to draw the attention of new customers. So when Gil decided to built a new personal Custom based on his 1942 Ford Coupe, he knew it needed to be superb, and recognisable as an Ayala Custom.

The top was chopped in an almost fast back way with the rear of the top chopped considerably more than the front for the ultimate Ayala smooth look. The drip rails were of course shaved and the rear quarter windows were completely reshaped to fit the new roof profile. All four fenders were molded to the body and using shaped sheet metal and lead they were flared into the body. All the exterior trim, except the windshield and rear window frames was removed and holes filled and the body smoothed. Taillight pods were hand shaped and molded into the fender flowing with the line of the long fender skirt, and echoing the shape of the rear, molden in, slash pan. The running boards were removed and new covers created and molded to the lower part of the body for a much smoother lower half of the car. Once done, Gil did not even instal a set of Appleton Spotlights to break up the super smooth body. It is as if Gil wanted to say “looks at all the smooth body work we did on my car. It is super straight, and flows from front to real and has no extra chrome trim or accessories to be pleasing to the eye.”

Side view shows how extreme the chopin Gil’s personal ’42 Ford Coupe is and how beautifully it flows into the trunk. The side trim was removed, but the belt-line was left sharp on this car, and not filled with lead like how it was done on Jack Stewart’s Ford and Louis Bettancourt’s 49 Mercury.

Side view shows how extreme the chopin Gil’s personal ’42 Ford Coupe is and how beautifully it flows into the trunk. The side trim was removed, but the belt-line was left sharp on this car, and not filled with lead like how it was done on Jack Stewart’s Ford and Louis Bettancourt’s 49 Mercury.

[divider]

The chopped roof looks even more extreme from the rear. Most likely Al used California Metal shaping to create the new sail paneles needed to make this chop work as good as id does. The moulded in rear fenders looks perfect in stye with the whole smooth appearance of the rear of the car.

The chopped roof looks even more extreme from the rear. Most likely Al used California Metal shaping to create the new sail paneles needed to make this chop work as good as id does. The moulded in rear fenders looks perfect in stye with the whole smooth appearance of the rear of the car.

[divider]

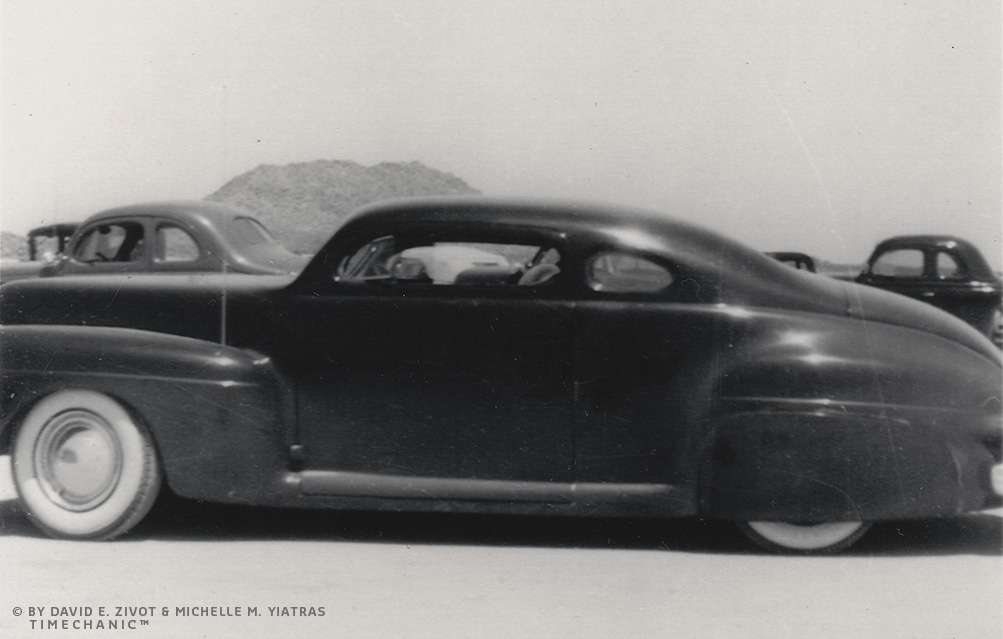

Profile view shows the incredible flow of the chopped top, and how the curves of the top have the same feel as the shape of the molded in fenders.

Profile view shows the incredible flow of the chopped top, and how the curves of the top have the same feel as the shape of the molded in fenders.

[divider]

Flow from the roof into the trunk, it does not get any smoother than this. This photo also shows the smooth curved shape of the molded fenders, and how the molded in running boards help with the overall smooth look of the car. Absence of side trim only works because of the careful designed flow of the body.

Flow from the roof into the trunk, it does not get any smoother than this. This photo also shows the smooth curved shape of the molded fenders, and how the molded in running boards help with the overall smooth look of the car. Absence of side trim only works because of the careful designed flow of the body.

[divider]

Louis Bettancourt 1949 Mercury

Another great sample of the look is the 1949 Mercury the Ayala’s created for Louis Bettancourt. It belongs to one of the first 49-51 Mercury’s that were chopped and the lines on this custom are truly unique. Especially if you pay close attention to all the details Al added to this car. The car was stripped from all its trim, except the windshield and rear window trim. Even the side window trim was removed and to make it even smoother the body lines around the windows were leaded smooth.

The car was chopped with a wonderful flow and balance. The way the top flows into the trunk is enhanced by the unusual large radius added to the trunk corners. This new line helps the top flow much better into the trunk section. The drip rail was shaved and the door tops reshaped and rounded. One trick on this car that must have taken a lot of time to do, and which goes unnoticed a lot, is that the B-pillar on the door was narrowed to get in balance with the B-pillar on the rear quarter window. Just another major touch that helps with the balance and flow.

The rear view of the Louis Bettancourt Mercury shows the hand shaped taillights made to fit with the smoothed body. The top trunk corners were reshaped to make the roof flow nicer into the trunk. The fade away fenders flow from the headlights all the way to the rear portion of the rear fender where its shape was echoed by the custom made taillight lip.

The rear view of the Louis Bettancourt Mercury shows the hand shaped taillights made to fit with the smoothed body. The top trunk corners were reshaped to make the roof flow nicer into the trunk. The fade away fenders flow from the headlights all the way to the rear portion of the rear fender where its shape was echoed by the custom made taillight lip.

[divider]

This side view of the Bettancourt Merc shows the modifications done to the B-pillar and how the side windows and belt line were completely smoothed.

This side view of the Bettancourt Merc shows the modifications done to the B-pillar and how the side windows and belt line were completely smoothed.

[divider]

The first version of the Bettancourt Mercury shows the use of very little chrome. Simple but elegant 1951 Kaiser grille bar, bumpers, windshield surround and door mounted Appleton Spotlights is the only chrome. The rest of the body is molded and all corners rounded. Notice how the rear hood corner shape makes it easier to make the transition to the windshield.

[divider]

All fender panels were welded to the body and smoothed, the dog dip on the door was streamlined for a full fade away effect. The grille surround was molded in, and a second surround flipped and repeated on the bottom. The hood corners on the front were rounded with an radius that matched the grille opening. The rear corners of the hood also had a large radius added. which helped the eye with the flow of the front to the top. The molded in taillights have a molded in lip that has a similar smaller radius as used elsewhere on the car. The first version of this car was finished by the Ayala’s in a lime gold and the car only had chrome on the bumpers, grille, the spotlights, and the window trim front and rear.

The car must have looked stunning like this. But not too long after that it was restyled by the Barris Shop, and some more chrome details were added including a Cadillac side trim. But still after that the Ayala Streamline molded look was still very evident.

The Barris version of the Bettancourt Mercury shows a new grille, bumpers and side trim. But the main smoothed body theme still remains The dark maroon paint shows of the smoothed body lines even better.

The Barris version of the Bettancourt Mercury shows a new grille, bumpers and side trim. But the main smoothed body theme still remains The dark maroon paint shows of the smoothed body lines even better.

[divider]

Close up of the B-Pillar work done by the Ayala’s. The door corners are rounded, and door line is now centred in the B-pillar. The window opening edges are leaded smooth and so is the belt-line. Flow.

Close up of the B-Pillar work done by the Ayala’s. The door corners are rounded, and door line is now centred in the B-pillar. The window opening edges are leaded smooth and so is the belt-line. Flow.

[divider]

Buddy Alcorn 1950 Mercury

This 1950 Mercury was restyled mostly by the Ayala’s for an unknown owner in the early 1950’s. This photo of the unfinished car appeared in the 1952 edition of the Dan Post Blue Book of Custom Restyling. Most likely the car was finished in this version, but so far no photos of it have surfaced from this version. All we have are two set free from the background photos from the Dan Post Blue Book of Custom Restyling. What we can see in these photos is the super smooth flowing near fast back style chopped top with the drip rails removed and angled forward B-Pillard. Full fade away fenders with all body lines molded in and the use of early 1950’s Oldsmobile rear fenders and taillights.

In progress photos, most likely taken at the Ayala shop shows the beautiful flowing lines of the chopped top and the full fade away fender line.

In progress photos, most likely taken at the Ayala shop shows the beautiful flowing lines of the chopped top and the full fade away fender line.

[divider]

Later, in 1955 Buddy Alcorn bought the Mercury and took it to the Barris shop for an update. The Barris shop added the side trim with rear quarter panel scoop and reshaped the rear fenders to accept a set of 1955 Plymouth taillights. This photo shows how much the top trunk corners are rounded to flow with the super smooth chopped top.

Later, in 1955 Buddy Alcorn bought the Mercury and took it to the Barris shop for an update. The Barris shop added the side trim with rear quarter panel scoop and reshaped the rear fenders to accept a set of 1955 Plymouth taillights. This photo shows how much the top trunk corners are rounded to flow with the super smooth chopped top.

[divider]

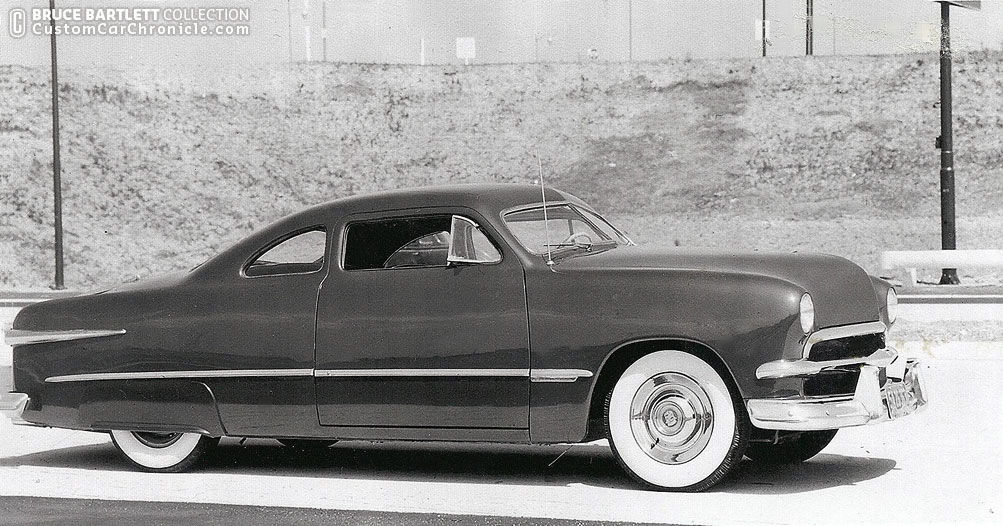

Jim McClarens 1949 Ford

Jim-McClaren’s 1949 Ford coupe it perhaps a bit different from the other cars in this article because it does have chrome side trim and even chrome 1951 taillight wind-splits. But I wanted to include the car in this article to show how the Ayala’s chopped this very hard to chop coupe, and how all the detail lines on the top, including the belt line are molded in and smoothed. The rear quarter windows were heavily reshaped to work with the flow of the top, and to blend the doors into the rear quarter window the top corners where rounded with a nice large radius. All this created the unique Ayala look.

When Bruce Bartlett shared this picture he asked me if I had any idea who had built it for his friend Jim McClarens. Based on the incredible looking chopped top with its smooth look and feel I said. “This must be an Ayala Custom!” Correct Bruce said.

When Bruce Bartlett shared this picture he asked me if I had any idea who had built it for his friend Jim McClarens. Based on the incredible looking chopped top with its smooth look and feel I said. “This must be an Ayala Custom!” Correct Bruce said.

[divider]

(This article is made possible by)

(This article is made possible by)

![]()

What a clinic you have given us, Rik. Your explanations point us to the details that contribute, element-by-element, to that overall smooth flow of lines that the Ayalas set for custom styling. Their artistry stands out. A beacon for all that followed. What strikes me, as you describe, are the formed shapes, not just borrowed parts from newer and more “upscale” factory models, as would appear increasingly into the Fifties. This was true customizing, by unquestionable masters of the artform. Thanks for your trip back in time, Rik. Thanks, Memo, for the light you always play onto our understandings.

It doesn’t get any better than this. Long live the CCC.

All of the above ^^^^^^^ X’s 2.

Torchie

Rik, Larry always expresses things better than I, but I wanted to comment just so you know I’m watching and reading these extremely insightful views into our customizing roots. Thank you once again for a great article!

Dave

Great feature Rik, awesome detail and you know much I love the Ayalas. I love reading stuff….

Thanks guys… makes me happy you enjoyed this one. Been wanting to do this for a long time.

what an amazing article rik this is awesome the story on gill an al the ayala brothers an the great kustoms they did u out did ur self on this article love all the kustoms that u showed us an the details u pointed out on each one of them , the photos were all awesome long live rik an the ccc,

I love the Ayala look and this article highlights some of the best examples. It’s interesting to google map the locations of the Ayala shop and CMS- both still there and only a few miles apart. I recently met a guy here in Lake Elsinore who worked at CMS in the early ’50s- Bob Behrens- he is now 82 and had a long career building aluminum drag racing bodies. He is sharp as a tack and remembers visiting Barris Kustoms and having them come to get panels formed…I will make it a point to ask what he remembers from Gil and Al…perhaps he has some cool insight to share with us.

I love the recent focus on the Ayalas, Rik…they built some killer kustoms. You’re so right about the removal of trim being a dangerous move when it comes to smoothing out a kustom. I have seen a number of cars that have fallen victim to people just taking everything off because it came with it from the factory. A careful eye for the right trim- or removal of trim- is a special talent.

Great article Rik! I love the Ayala look and it nice to see it so well documented.